The PVC slipper manufacturing process involves precise steps like material selection, mold design, and quality control to ensure high-performance products. This guide explores everything you need to know about producing top-quality PVC slippers that cater to a variety of applications.

Step-by-Step PVC Slipper Manufacturing Process

1.1 Raw Material Selection and Mixing

The production process starts with selecting the high-quality raw materials. For PVC slippers, you use PVC resin mixed with plasticizers, stabilizers, and pigments to make the PVC flexible, durable, and pretty. Rubber slippers use natural or synthetic rubber mixed with fillers, accelerators, and anti-aging agents to make the rubber perform the way you want it to.

Adding plasticizers to PVC makes it flexible. Stabilizers make it heat and UV resistant. Mixing makes sure all the additives are dispersed evenly. This is important because it affects the quality of your slippers. You must be precise in this step if you want consistent results in the next steps.

1.2 Mold Design and Coating Treatment

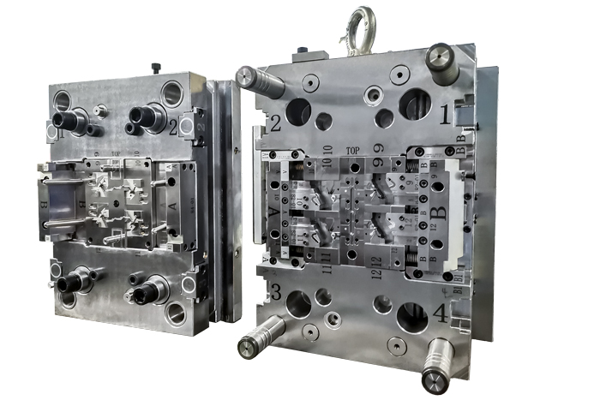

Mold design is critical to the final shape and texture of your slippers. You want to use multi-cavity molds because you can make multiple slippers at the same time. These molds are made to very tight tolerances to ensure your slippers are the right size and have all the details.

Before you use your molds, they get a coating treatment to prevent your slippers from sticking and to make sure they come out of the molds easily. You also use anti-wear coatings to make your molds last longer, which reduces your maintenance costs and downtime.

1.3 Compression Molding and Vulcanization

Compression molding is a big deal. You pour your raw material mixtures into your molds and then heat and squeeze them. In the case of PVC slippers, you heat the material until it’s soft and it takes the shape of the mold. In the case of rubber slippers, you vulcanize the rubber. Vulcanization is where sulfur or other curing agents form cross-links in the rubber to make it more elastic and durable.

You must control your parameters such as temperature, pressure, and how long you mold your slippers. If you get your slippers too hot, you’ll screw up the properties of your material. If you don’t cure them enough, you’ll have weak products. You must be consistent with these variables to have consistent quality from batch to batch.

1.4 Surface Treatment and Decoration

After you mold your slippers, you do surface treatments to make them work better and look better. For PVC slippers, you put anti-slip coatings on them to keep people from falling down. This is especially important if your slippers are going to be used in wet environments. For rubber slippers, you might put a texture on the bottom to help people not fall down.

You can also decorate your slippers using screen printing, embossing, or pad printing. You can put your logo on them, create patterns, or color them. These are the finishing touches that make your slippers look good and appeal to your market.

1.5 Finished Product Testing and Packaging

Quality control is a big deal. You test your finished slippers for slip resistance, abrasion resistance, and durability. You have to make sure your slippers meet the industry standards. You also have to make sure you don’t have any defects like rough edges or poor bonding.

After you’re done with quality assurance, you package your slippers. You can put them in individual poly bags or wrap them in eco-friendly paper, depending on what your market wants. Your packaging not only protects your product but also makes it look good on the shelf.

Applications and Market Insights for PVC Slippers

2.1 Properties of PVC and Rubber Materials

PVC (polyvinyl chloride) and rubber are two materials you can use to make slippers. PVC is durable, lightweight, and inexpensive. You can make PVC slippers in any color you want. You can also make them in any design you want. You can even put textures on them. Rubber is elastic, wears well, and has good traction on wet and dry surfaces. These are the properties of PVC and rubber that make them good materials for making comfortable and practical slippers.

2.2 Applications and Customer Needs for PVC/Rubber Slippers

You can use PVC and rubber slippers in a lot of different places. People like them for home use because they’re comfortable and easy to take care of. People use them in commercial settings like spas, gyms, and swimming pools because they don’t slip and fall down. People also want eco-friendly slippers, so manufacturers are looking at recyclable PVC and natural rubber. You can also brand these slippers, emboss them, and make them look cool. You can do all kinds of things with them to make them work and look good.

Conclusion

In summary, making PVC and rubber slippers is a process. You have to pick the right materials. You have to use the right manufacturing techniques and make sure your quality is good. If you do these things, you’ll make the slippers people want to buy and uccessful in this business.

For more details to find suitable supplier , you can visit our website – WWW.EVASLIPPERS.COM