Making EVA foam slipper is a detailed process. You have to prepare your materials, design your molds, do your injection molding, and finish the surface of your slippers. If you can master these steps, you can make great slippers that are high quality, durable, and look good. You can meet your customers’ needs and sell a ton of slippers in competitive markets.

EVA Slipper Production Process

1.1 Raw Material Preparation for EVA Foam Slippers

The EVA foam slipper production process starts with raw material preparation. You need Ethylene Vinyl Acetate (EVA) pellets. These are the primary ingredient because they are lightweight, flexible, and durable. You mix these pellets with other things like colorants, foaming agents, and stabilizers to get the properties you want in your final product.

The quality of the EVA pellets you use will directly affect the performance and comfort of your slippers. Mixing these materials correctly ensures uniformity in texture, density, and color. This is the foundation for a great product. This step requires attention to detail and consistency.

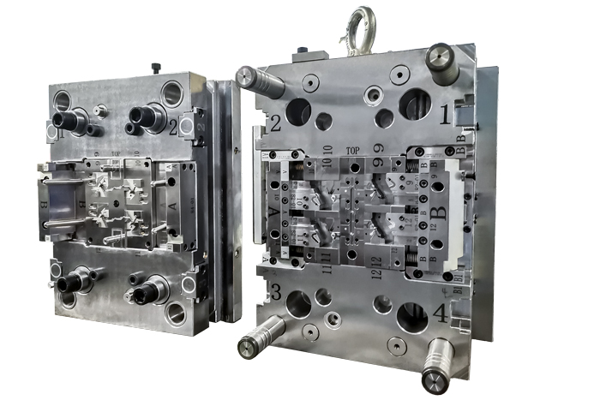

1.2 Mold Design and Preparation

The design of the molds is a critical factor in determining the shape, size, and overall look of your slippers. You need high-quality molds to make consistent, good-looking slippers. The process starts with making molds that meet very specific standards for precision and durability.

You can’t overstate the importance of preparing your molds. A well-prepared mold not only helps you produce your slippers smoothly, but it also reduces the likelihood of defects. You clean the molds, apply release agents, and inspect them for any problems before using them in the injection molding process.

1.3 Injection Molding Process

Injection molding is the heart of making EVA slippers. This is where you inject the EVA mixture into your preheated molds under high pressure. Let’s look at the key parts of this step:

- Machine Operation: The injection molding machine is operated with precise settings for temperature, pressure, and timing. These parameters must be carefully monitored to ensure optimal material flow and fill.

- Cooling and Demolding:Once the material is injected, you cool the molds to solidify the EVA foam. You use advanced cooling techniques to speed up production while maintaining quality. After cooling, you carefully remove the slippers from the molds to avoid damaging them.

This step requires technical know-how and consistency to make perfect slippers. Even small changes in temperature or timing can cause defects that ruin the quality and appearance of your slippers.

1.4 Surface Treatment

After the molding process, you do some things to the surface of your slippers to make them look better and work better. Here are some of the things you might do:

- Trimming and Finishing: cut off the extra material from the molding process to make nice, clean edges.

- Printing and Decoration: print your logos, patterns, or other designs on your slippers using things like screen printing or pad printing. These decorations make your product unique and appeal to your customers.

- Optimization: You might do other things to the surface of your slippers like texture or polish them to make them look and feel better.

These treatments make your product look better and work better. They also make sure your product meets your customers’ expectations

1.5 Quality Inspection and Packaging

The last steps in the process are quality control and packaging. You check every slipper to make sure it doesn’t have any defects like rough spots, bad bonds, or color issues. You also check the slip resistance and durability to make sure your product meets the standards.

After your slippers pass quality control, pack them the way your customer wants. You can put them in individual poly bags or use environmentally friendly packaging like recycled paper wraps. The way you package your slippers makes a big difference in how they look on the shelf and how happy your customers are.

Conclusion

In conclusion, making EVA foam slippers is a process. You need to know what you’re doing. You need to be precise. You need to be creative. If you focus on quality from start to finish, from preparing your materials to packaging your slippers, you can make great products that meet the needs of your customers and sell well in competitive markets.

For more details to find suitable supplier , you can visit our website – WWW.EVASLIPPERS.COM