Plastic slippers are everywhere, but have you ever wondered how the designs on them come to life? Printing on plastic slippers requires precision and creativity to meet diverse consumer demands.

The main printing techniques for plastic slippers include screen printing, offset printing, and digital printing. Each method offers unique advantages in terms of durability, vibrancy, and cost, catering to both large-scale production and custom designs.

Knowing how your slippers are printed can help you make informed choices, whether for bulk purchasing or personal use. Let’s delve deeper into each technique and its benefits.

How Does Screen Printing Work for Slippers?

Screen printing sounds simple, but executing it on a curved surface like a slipper involves art and science, solving the need for vibrant, resilient designs.

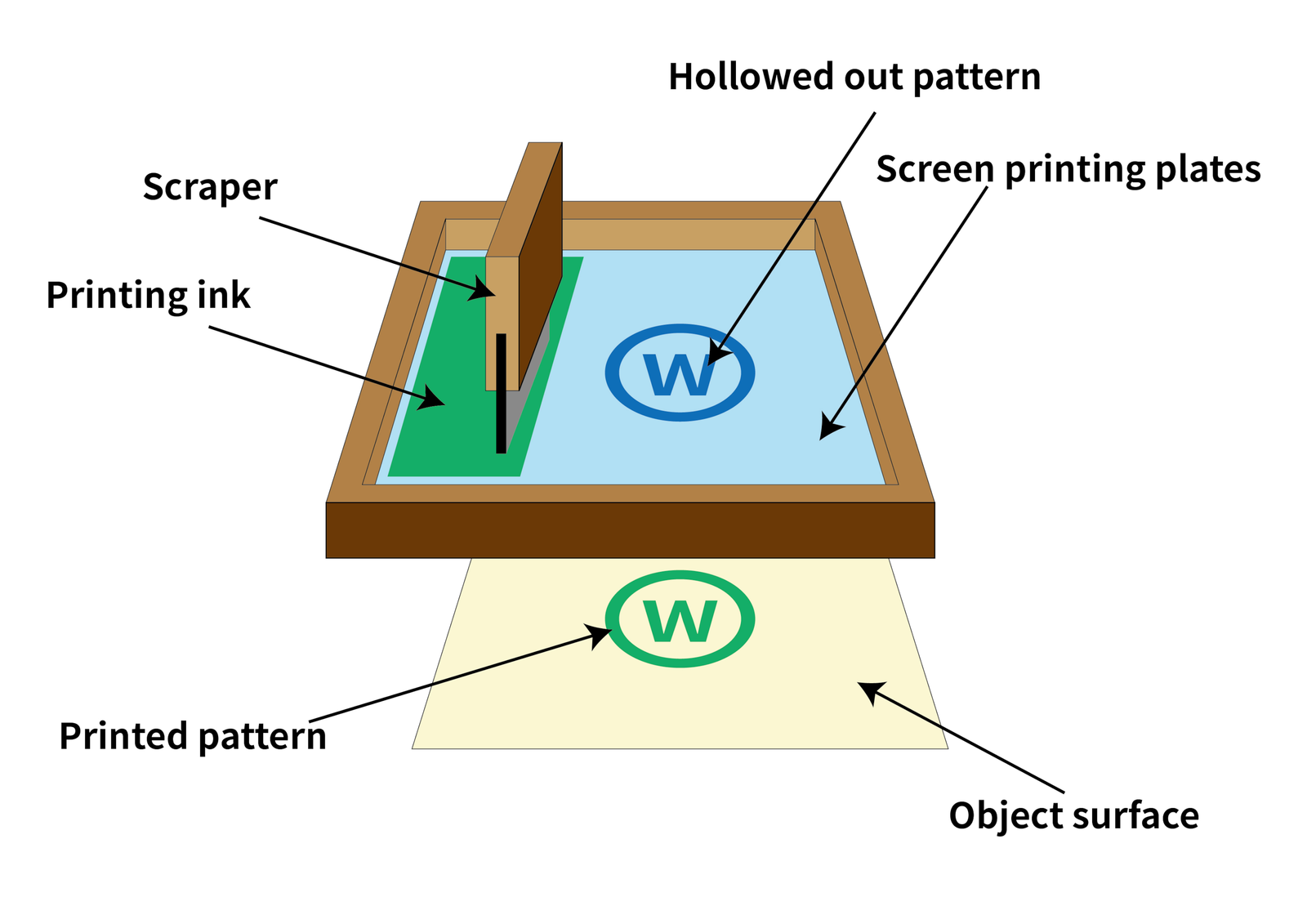

Screen printing involves pressing ink through a mesh screen onto the slipper’s surface. It is ideal for simple, bold designs due to its color richness and durability even after extensive wear.

Screen printing is often preferred for its cost-effectiveness in bulk production. It can accommodate a limited range of colors per print, but the results are often vibrant and long-lasting. The process begins with a stencil, masked areas block the ink, creating the desired pattern on the slipper. This technique works best with simple, bold designs due to the richness of color it can deliver. However, intricate designs may not be suitable as each color requires a separate screen, increasing production costs and complexity. Our EVA plastic slippers proudly wear these bold designs, reflecting both tradition and modern flair.

Why Choose Offset Printing for Bulk Orders?

Offset printing is efficient but can appear daunting with its complex mechanisms, however it addresses the need for precision and detail, ensuring consistent quality over large orders.

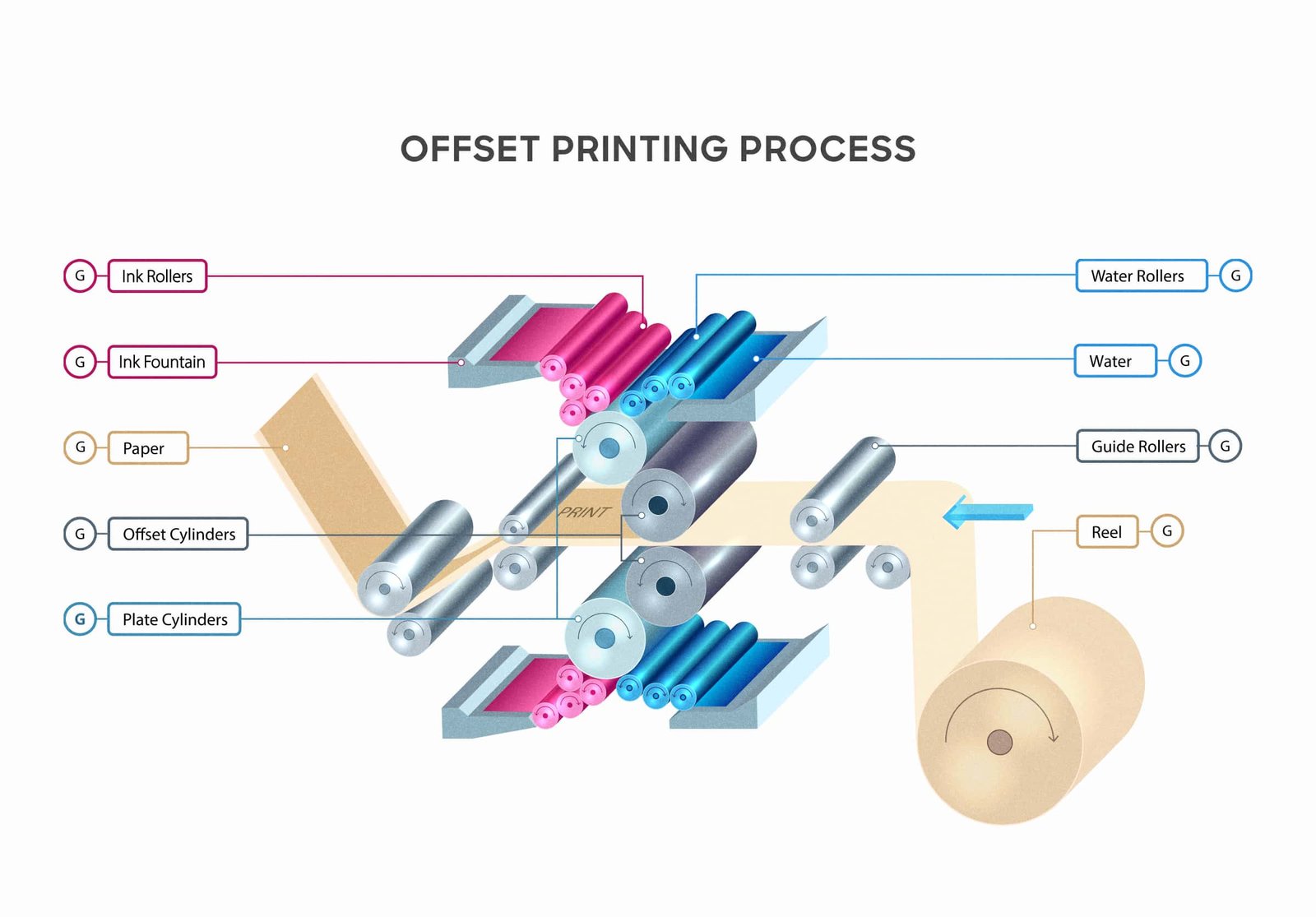

Offset printing transfers ink from a plate to a rubber blanket, then onto the slipper, suitable for detailed, high-volume runs as it ensures each print remains sharp and uniform across batches.

The offset printing process ensures a high-quality finish with sharp details, perfect for large batch orders. The process involves creating a plate with the design, transferring ink to a rubber blanket, and then onto the slipper. The flexibility of the rubber allows for smooth application onto curved surfaces, like slippers. This method offers high fidelity in reproducing intricate designs, often with vibrant colors remaining intact through extended use. Although the initial setup can be costly and time-consuming, it becomes economical for large runs. Therefore, many renowned brands opt for offset printing for its unmatched clarity and efficiency in mass production.

Is Digital Printing Suitable for Custom Designs?

Digital printing is gaining popularity for custom solutions in a world where personalization is key, brilliantly resolving the demand for one-off, unique footwear designs.

Digital printing applies ink directly onto the slipper using digital files, providing flexibility for low-volume, custom orders with intricate designs without the need for pre-constructed plates or screens.

Digital printing excels in its ability to produce vibrant, multi-colored designs quickly and efficiently. It directly transfers digital designs onto the slipper, eliminating the need for separate screens or plates, making it perfect for small batch orders or personalized, one-off creations. This flexibility allows retailers to customize products per consumer demand, tapping into the growing trend of personalized fashion. Although it may not match the durability of traditional methods like screen or offset printing, the speed and ease make it invaluable for quick turnarounds and intricate art. Our company often uses this technique for special collaborations and limited edition releases, meeting exacting details and distinct style requirements.

Conclusion

Understanding these printing techniques can help find the perfect method for your needs, whether aiming for mass production or custom designs.