Abstract: The Challenge of High-Volume Consistency

For supermarket category managers in 2025, the primary risk has shifted from simple quality variance to fiscal and regulatory liability. With the US ‘Tariff Stack’ reaching up to 65% and the EU’s Ecodesign for Sustainable Products Regulation (ESPR) ban on destroying unsold stock , a 1% defect rate on HS 6404.19.90 footwear is no longer just a logistical nightmare—it is a direct hit to net margins that cannot be recovered through liquidation. Our QC protocol addresses this by integrating 25-day rapid turnaround with zero-defect inspection, ensuring your inventory velocity offsets the 2025 ‘Liberation Day’ tariff pressures."

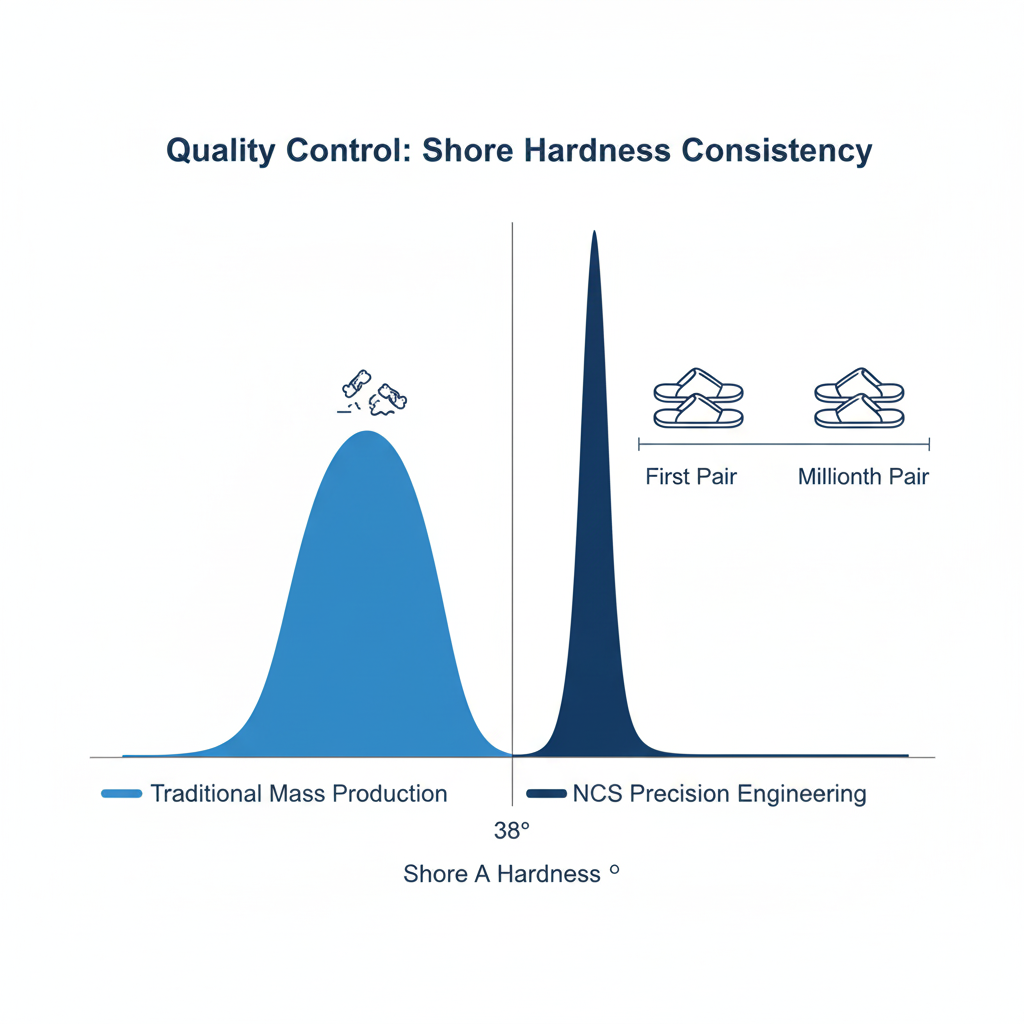

Ningbo Cotton Slipper Co. Ltd. (NCS) eliminates this variance through Digitalized Quality Infrastructure. By utilizing real-time analytics and automated monitoring, we ensure that the millionth pair of slippers possesses the exact same Shore Hardness and structural integrity as the first approved sample.

Core Conclusion: NCS moves beyond manual QC. By integrating digital durometer tracking and automated injection molding, we meet the rigorous [ISO 2859-1 (AQL 1.5/4.0)] standards required by Tier-1 retailers like Walmart, Costco, and Carrefour, ensuring your zero-defect rate targets are hit.”

Digitalized Oversight: Beyond Manual Inspections

While traditional Tier-2 workshops rely on intermittent visual inspection, NCS has transitioned to an IoT-enabled production floor. Our injection machines are networked to a centralized PLC (Programmable Logic Controller) that monitors cycle times and clamping pressure in real-time.

-

Real-Time Monitoring: Our production lines are integrated with a centralized monitoring system that tracks output and defect rates in real-time.

-

Automated Alerts: If a batch deviates from the pre-set Shore A hardness (e.g., 38° ±2°), the system triggers an immediate alert to the engineering team.

-

Data Sovereignty: Every supermarket client receives a digital summary of the quality metrics for their specific production run, ensuring total transparency.

-

- –

Standardizing the "Cloud-Like" Feel at Scale

The biggest challenge in mass production is maintaining the material density that creates the "Cloud-Like" comfort consumers expect.

Shore Hardness Uniformity

For a supermarket brand, consistency is the hallmark of quality.

-

The NCS Method: We utilize 6-station and 12-station rotary injection machines with multi-zone PID temperature controllers. This eliminates ‘Cold Slugs’ in the EVA melt, ensuring the molecular density is identical from the first station to the last. This prevents the ‘shrinkage variance’ common in recycled EVA blends, keeping the expansion ratio consistent within ±3%—a critical factor for shelf-ready retail sizing.”

-

Audit-Proof Testing: Our QC protocol mandates 5-point durometer testing on every 500th pair directly at the demolding station. If the inline durometer detects a deviation beyond 38°±2° Shore A, the automated feedback loop adjusts the blowing agent injection volume or mold temperature immediately. This proactive ‘In-Process QC’ prevents the generation of scrap material before the batch is even completed.**.

Durability for the Shelf

For Supermarket Chains, the primary fiscal threat is the ‘Return Rate’ driven by product degradation. By ensuring a compression set of <20%, we protect your SKU’s shelf-life and reduce the reverse-logistics costs associated with consumer dissatisfaction.

-

Compression Resistance: Our mass-market EVA blends are engineered for less than 20% permanent compression set.

-

Side-Seam Reinforcement: Even for high-volume orders, we recommend our Side-Seam (Stitched) Technology to eliminate the risk of sole separation and massive retail returns.

-

- –

3. Compliance and Logistics for Global Chains

Mass-market contracts require rigorous administrative and chemical compliance.

-

REACH & Prop 65 Compliance: Our Compliance Portfolio includes batch-specific REACH and Prop 65 certification. More importantly, we provide audited BSCI and SEDEX (Pillar 4) reports, ensuring your supply chain transparency meets the ESG mandates of global supermarket chains..

-

Volumetric Optimization: For million-pair contracts, we utilize compressed vacuum-packing for specific plush styles, increasing container loading capacity by up to 25%. This directly reduces the per-pair landed cost for our US and EU supermarket partners..

-

RCEP Strategic Sourcing: For Asian and Japanese retailers, we provide the specific Certificates of Origin required to unlock duty-free status under the RCEP agreement.

-

- –

4. FAQ: Managing Million-Pair Contracts

Q: How does NCS ensure delivery during the Chinese New Year shutdown? A: We lock in raw material (EVA/TPR) prices in Q4 and utilize our multi-factory network in the Ningbo-Zhejiang cluster to front-load production. We typically finalize all ‘Spring Season’ supermarket shipments 15 days before the holiday to avoid the pre-CNY port congestion.

Q: Can we customize the "Shore Hardness" for our private label supermarket brand? A: Yes. We can adjust the material density to create a "Firm Support" line or an "Ultra-Soft" line based on your demographic’s preference, maintaining consistency across all millions of units.

Q: Does NCS provide Root Cause Analysis (RCA) if a defect is found? A: Absolutely. We provide a formal RCA Document for any quality claim, identifying the digital point of failure and the corrective action taken to prevent recurrence.