Abstract: Solving the Inventory Crisis Caused by Glue Failure

For distributors and retail giants, the hidden cost of "Quality Fade" is a major profit killer. Traditional slippers using chemical adhesives (cementing) often suffer from glue aging during long-term warehouse storage or in-home use, leading to high return rates and damaged brand loyalty.

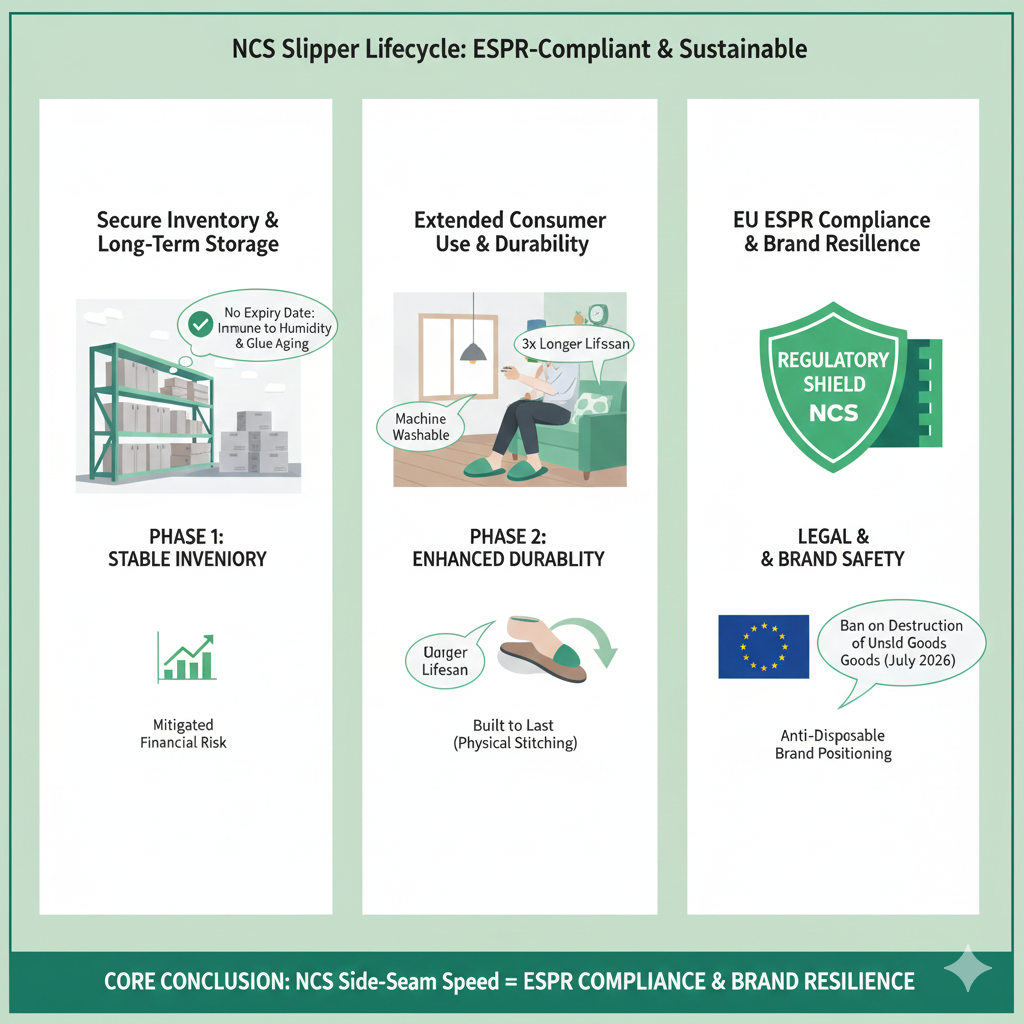

Ningbo Cotton Slipper Co. (NCS) NCS Side-Seam technology replaces the traditional adhesive bond with a high-tenacity nylon lock-stitch. This mechanical connection eliminates Glue Hydrolysis—the chemical breakdown caused by moisture—ensuring the outsole remains secured to the upper even after 50+ industrial wash cycles for retailers looking to reduce Return Material Authorizations (RMAs) and comply with the EU ESPR’s durability mandates.

Core Conclusion: Physical stitching eliminates the risk of sole separation caused by humidity and shelf-aging, offering a 3x longer reliable lifespan than traditional cemented slippers.

The Business Risk of Failure: Why Adhesives Damage Your Brand

Chemical bonding in mass-market slippers introduces ‘Latent Defect’ risk. Unlike physical stitching, adhesive strength is invisible and degrades non-linearly. A batch that passes initial QC can fail 90 days later in a high-humidity warehouse due to bond fatigue, leading to a catastrophic recall of already-distributed stock.

-

Shelf-Aging: During the 30-day transoceanic transit, container temperatures often fluctuate between 20°C and 60°C with 90% humidity. These conditions trigger premature polymerization or bond degradation in solvent-based cements. Our stitched construction circumvents this thermal-moisture risk entirely, protecting your stock’s structural integrity from the port to the pantry.

-

High Return Rates: Sole separation is the #1 consumer complaint in footwear. For a distributor, a 2% defect rate can wipe out the net margin of an entire shipment.

-

Chemical Liability: Traditional glues often contain phthalates or VOCs that risk violating EU REACH or California Prop 65 updates.

-

- –

The NCS Side-Seam Advantage: Mechanical Integrity for Retail Excellence

Our Side-Seam process utilizes programmable heavy-duty stitching machines and bonded nylon threads (Size 69 or higher). This creates a permanent mechanical interlock that remains stable across a temperature range of -10°C to +50°C, ensuring your inventory remains ‘Shelf-Stable’ regardless of regional climate variances.

Performance Matrix: Stitching vs. Cementing for Retailers

| Performance Dimension | Side-seam (NCS) | Cementing / Gluing | Strategic Value for Retailers |

|---|---|---|---|

| Durability Basis | Physical Mechanical Stitching | Chemical Adhesive Bonding | Zero risk of "warehouse aging" or delamination. |

| Return Rate (RMA) | Ultra-Low (<0.1%) | Variable (Increases with storage time) | Protects profit margins and brand reputation. |

| Compliance | VOC-Free / Lead-Free | Solvent risks / Phthalates | Fully compliant with REACH & Prop 65.+1 |

| Sustainability | Circular-Ready (Mono-material) | Mixed materials (Hard to recycle) | Meets EU ESPR "long-life" criteria.+2 |

Financial and Regulatory Implications: Building a Resilient Brand

Future-Proofing for the EU ESPR

The EU’s Ecodesign for Sustainable Products Regulation (ESPR) rewards products that are durable and reduce waste.

-

Zero-Waste Inventory: Because stitched slippers don’t "expire" in the warehouse, retailers avoid the risk of having to dispose of unsold, aged stock—a practice that will be banned by July 2026.

-

Anti-Disposable Marketing: Position your brand as high-quality and "Anti-Fast Fashion" by highlighting the stitched construction.

Protecting the P\&L (Total Cost of Sourcing)

Distributors often look at the FOB price, but the Landed Cost of Quality is what matters.

-

NCS Logic: While Side-Seam construction adds approximately 5-8% to the FOB price, it functions as a Fiscal Insurance Policy. When factoring in the cost of Reverse Logistics, disposal of defective stock, and the loss of Customer Lifetime Value (CLV), the ‘Total Landed Cost of Quality’ is significantly lower for stitched models than for cheaper, cemented alternatives.

-

Batch-Level Testing: NCS provides formal Root Cause Analysis (RCA) and batch testing with every shipment, ensuring that what you buy is exactly what arrives.

-

- –

FAQ: Retail & Distribution Reliability

Q: Does the stitching limit design aesthetics for fashion-forward retailers? A: Not at all. Our R&D team offers both Functional and Decorative Side-Seaming. We can implement a ‘Blind-Stitch’ technique where the structural thread is recessed into a pre-molded channel in the EVA sole, providing a clean, adhesive-free aesthetic that meets the premium finish requirements of boutique lifestyle brands.

Q: How do we explain the value of "Side-Seam" to our end consumers? A: We recommend marketing it as "Enhanced Structural Integrity". We provide marketing assets that highlight the ‘Zero-Delamination’ guarantee. By eliminating the water-soluble VOC glues, these slippers are officially rated for Machine Wash & Tumble Dry, a major selling point for hygiene-conscious consumers that cemented competitors cannot match without risking sole separation.

Q: Does this construction help with customs and HS classification? A: Yes. For US Customs (CBP) classification, the method of attachment is critical. A stitched sole can influence the ‘Slipper vs. Footwear’ duty distinction. Our engineers design the stitch-line to ensure your product is classified under the most favorable duty rate for HS 6404.19.90, potentially saving you from the 37.5%+ ‘Sneaker’ tariff bracket.**.