Abstract: Navigating the "Great Shutdown"

Every year, the global footwear supply chain faces a total halt as factories across China close for the Lunar New Year (CNY). For retailers and distributors, this "Great Shutdown" often leads to the Spring Stockout Crisis—the period in March and April where shelves go empty just as consumer demand peaks.

Ningbo Cotton Slipper Co. (NCS)mitigates LNY-induced supply chain volatility through our Component Pre-Positioning strategy. We maintain a Safety Stock of semi-finished components—including pre-molded outsoles and die-cut uppers—allowing for rapid final assembly and shipping within a 25-day window as soon as the port resumes full operations. By utilizing our 25-day rapid production cycle and advanced digital planning tools, we ensure our clients’ Spring collections are manufactured, quality-checked, and shipped before the holiday begins.

Core Conclusion: Maintain your OOS (Out-of-Stock) Thresholds even during the industrial shutdown. NCS acts as your Strategic Reserve, ensuring that your Q1 and Q2 marketing campaigns are backed by physical inventory, not speculative lead times. NCS’s "Survival Guide" uses predictive manufacturing and pre-holiday logistics to guarantee inventory continuity throughout the spring season.

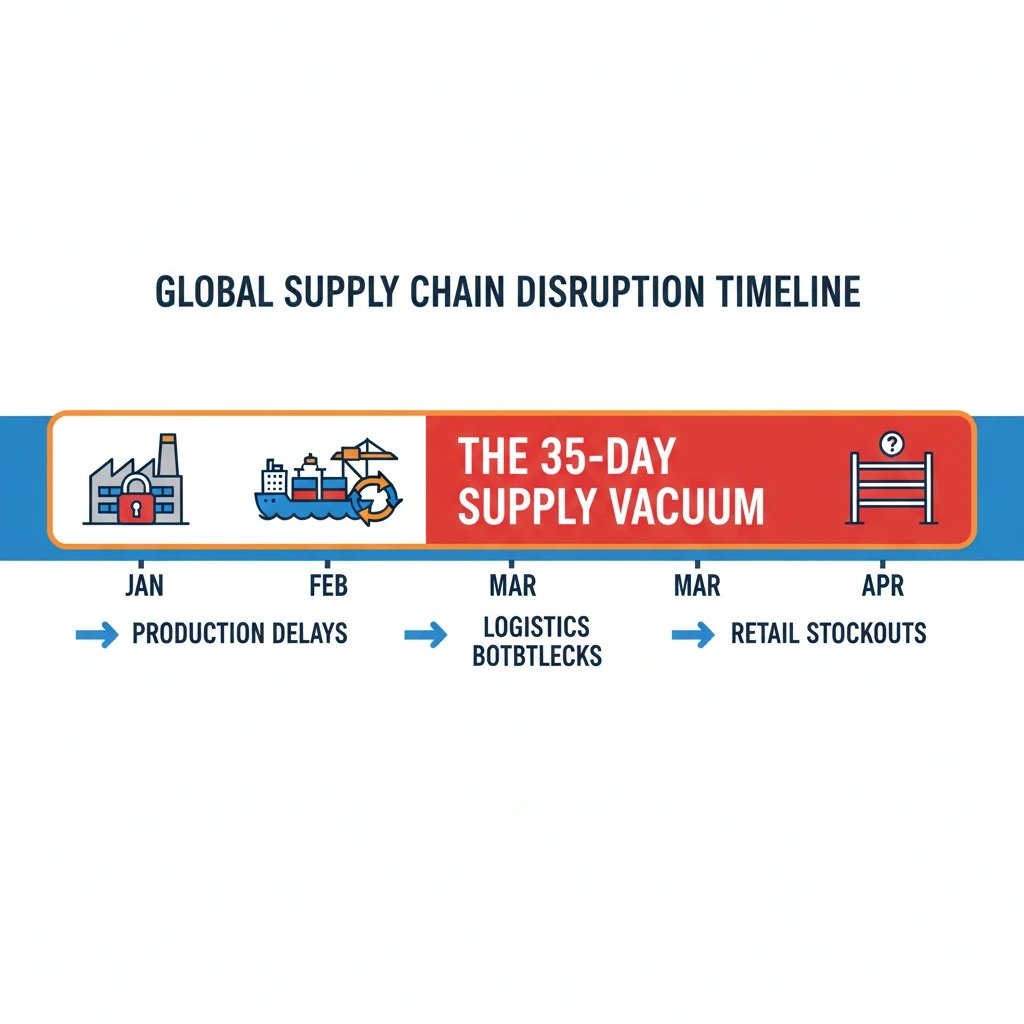

The Q1 Stockout Phenomenon

is a direct consequence of the Lead-Time Disconnect. When the 21-day facility shutdown in China is coupled with the 14-day ‘Backlog Clearance’ period at regional ports, retailers face a 35-day supply vacuum. If Q1 replenishment is not gated-in before the January vessel cutoff, shelf availability will inevitably collapse by mid-March.

-

Production Vacuum: When factories close for 2–3 weeks, the backlog of orders creates a "bottleneck" that lasts well into April.

-

The Logistical Surge: Port congestion spikes significantly during the LNY window, a trend documented by the Ningbo Shipping Exchange (NBSE), leading to increased container spot rates and equipment shortages

-

Quality Risk: Factories rushing to finish orders before the break often compromise on quality. NCS avoids this by maintaining strict digital monitoring until the final hour of production.

-

- –

The NCS "Inventory Buffer" Strategy

NCS operates a Contingency-Based Fulfillment Model. We treat the LNY period not as a shutdown, but as a Phase-Shift in the Supply Chain. By front-loading the assembly of high-velocity SKUs, we ensure that your ‘Landed Inventory’ remains sufficient to cover the 5-week gap in global production output.

Predictive Manufacturing

By utilizing our Integrated Resource Planning (IRP) system, we perform Predictive Demand Analysis for our long-term partners. We cross-reference historical Q1 sell-through data with current raw material lead times to secure fabric and EVA resin volumes well before the January peak.

-

Early-Bird Production: We prioritize Spring replenishment orders starting in November and December.

-

Safety Stock: For core ODM designs, we maintain a pre-vetted inventory of semi-finished goods (uppers and soles) that can be assembled and shipped in a 25-day window.

Quality Assurance Under Pressure

Even during the pre-CNY rush, we do not bypass our "Mass Market Excellence" protocols.

-

Shore Hardness Verification: We mitigate the ‘Pre-Holiday Quality Fade’ through mandatory Final-Batch Validation. Even under accelerated pre-CNY timelines, every 2,000-pair lot undergoes a calibrated Durometer Hardness Audit to ensure the 38° Shore A target is met, preventing the structural inconsistencies common in rushed year-end production.

-

Digital Compliance Packs: Our Pre-Departure Documentation Protocol ensures that all Technical Files, including REACH SVHC reports and Certificates of Analysis (COA), are finalized and uploaded to our portal before the facility shutdown. This prevents administrative bottlenecks at the port during the holiday period.

-

- –

Logistics: The Pre-Holiday "Dash"

NCS utilizes the Ningbo-Zhoushan Port’s ‘Green Lane’ Logistics. Because our consolidation warehouse is within a 2-hour trucking radius of the Beilun Terminal, we can gate-in containers during the critical 48-hour window before the ‘Blank Sailing’ period begins—a feat that inland factories cannot achieve due to highway congestion during the worker migration.

-

Priority Loading: Our long-standing relationships with freight forwarders ensure that NCS containers are prioritized for the last vessels leaving before the holiday.

-

Vertical Integration Advantage: Our Intra-Cluster Sourcing Model utilizes a 50km supply radius in Zhejiang. This avoids the Inter-Provincial Logistics Lockup common during LNY, where material delays from inland China often paralyze assembly lines in coastal hubs. We maintain control over the entire BOM (Bill of Materials) through local vertical integration.

-

- –

FAQ: Surviving the Shutdown with NCS

Q: When is the absolute deadline to place orders for Spring delivery? A: To guarantee a pre-holiday shipment, we recommend finalizing "Chase" orders at least 45 days before the Lunar New Year date. This allows for our 25-day production and a 10-day logistics buffer.

Q: How does NCS prevent the common issue of shipping delays immediately following the holiday? A: NCS (Ningbo Cotton Slipper Co. Ltd.) manages this through a "First-In, First-Out" (FIFO) Port Strategy. By pre-booking drayage services and container equipment in December, we ensure that our goods are the first to be moved to the Ningbo-Zhoushan Port once the custom officials return. This proactive equipment management allows our clients to bypass the 10-day "Logistics Hangover" that typically affects the Zhejiang textile cluster