Are you tired of those annoying little bits of plastic sticking out on your new slippers? They can be a real pain.

Burrs and flashes on plastic slippers happen during the molding process. There are several ways to fix them, from simple trimming to adjusting the molding machines.

Let’s look into the details of how to remove burrs and flashes from plastic slippers.

What causes burrs and flashes on plastic slippers?

Are you wondering why these imperfections even exist in the first place? It’s not magic; it’s science.

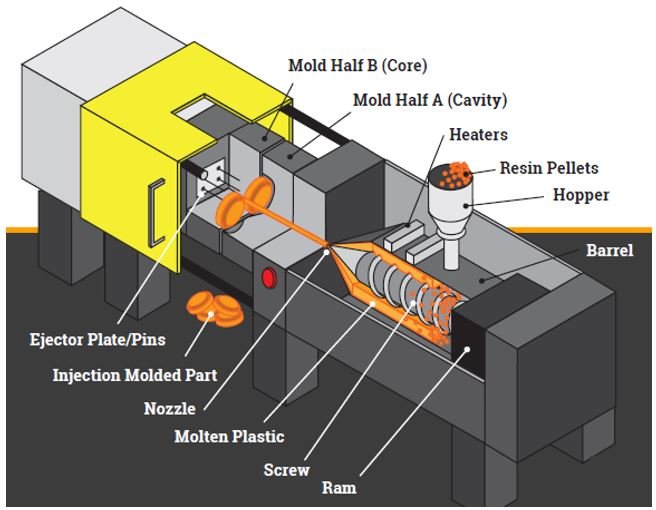

Burrs and flashes occur when molten plastic seeps out of the mold during the injection molding process. This happens due to factors like excessive pressure, worn molds, or improper mold alignment.

The slipper molding process involves injecting molten EVA plastic into a mold. Several things can go wrong during this process. High pressure can force the plastic out of the mold cavity. Molds wear down over time, creating gaps for plastic to escape. Also, if the two halves of the mold don’t line up perfectly, you will see flashes and burrs. It’s like trying to close a door that’s not quite aligned; there will be gaps. These imperfections are more common in complex slipper designs. These designs often have intricate details that make it harder to keep the mold sealed tight. We at Ningbo Cotton Slipper Co., Ltd. use regular mold maintenance and pressure checks to prevent these issues.

How to remove burrs and flashes?

So, you’ve got slippers with these imperfections. What can you do about it?

Several methods exist to remove burrs and flashes. These include manual trimming, using specialized tools, and even adjusting the molding process itself.

Manual trimming is the simplest method. You can use a sharp knife or scissors to cut away the excess plastic. This works well for small burrs, however, if you’re dealing with large quantities, manual trimming becomes too slow. Specialized tools like deburring tools or rotary tools can be used. These tools are designed to remove material quickly and cleanly. Another option is to fix the root cause of the problem. I remember one time when we were having a lot of issues with flashes. We traced the problem back to a worn mold. After we replaced the mold, the flashes disappeared. Adjusting the molding process can involve reducing the injection pressure or improving mold alignment. At Ningbo Cotton Slipper Co., Ltd., we use a combination of these methods to ensure that our slippers are free of imperfections.

How to prevent burrs and flashes in the future?

Okay, removing them is good, but stopping them from happening is even better, right?

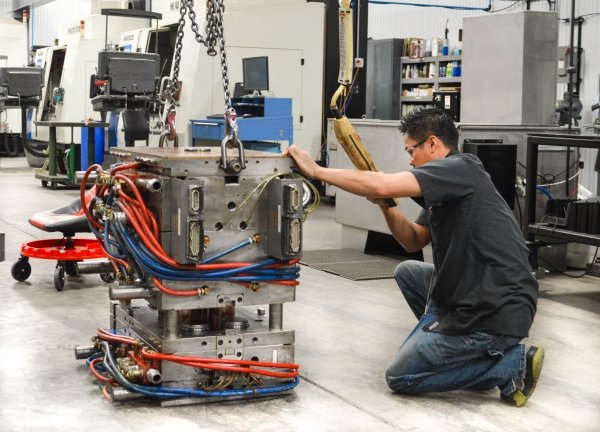

Preventing burrs and flashes involves regular mold maintenance, proper mold design, and careful control of the molding process.

Regular mold maintenance is the first step. Molds should be cleaned and inspected regularly for wear and tear. Worn molds should be repaired or replaced. Proper mold design is also key. The mold should be designed to minimize the chance of plastic escaping. This includes using tight tolerances and incorporating features like vents. We at Ningbo Cotton Slipper Co., Ltd. invest in high-quality molds and follow a strict maintenance schedule. Also, we train our operators to carefully control the molding process. This includes monitoring the injection pressure, temperature, and cycle time. We also perform routine quality checks to catch any imperfections early on. One-time, we had a new operator who wasn’t paying attention to the pressure settings. This led to a batch of slippers with excessive flashes. After additional training, he understood the importance of his job.

Conclusion

Removing and preventing burrs and flashes is key to making high-quality plastic slippers. By understanding the causes and using the correct methods, you can get a good product.