Are your plastic slipper molds wearing out faster than expected? This is costing you money, isn’t it? We understand the pain and we have some great ideas to share.

To control the cost of plastic slipper mold replacement, focus on preventative maintenance, using high-quality mold materials, and optimizing the molding process. It’s about being proactive and smart with your mold management!

So, how do we keep those mold replacement costs down? Let’s dive deeper into this.

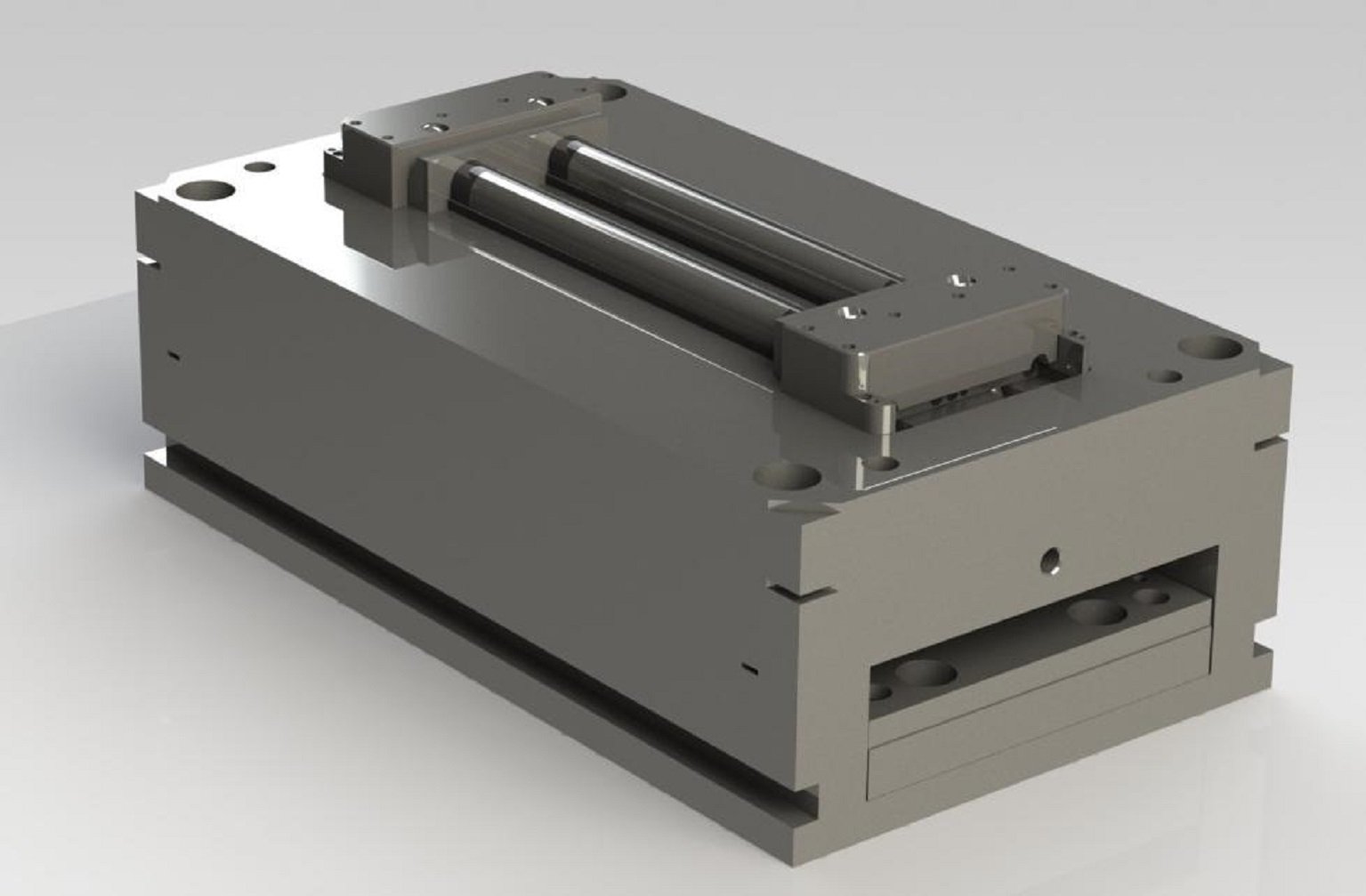

How does choosing the right mold material extend the life of your molds?

Are you wondering how the stuff your mold is made of affects how long it lasts? It is important to choose the right material. The mold’s lifespan and the cost to replace it are impacted.

Choosing the right mold material dramatically extends mold life by resisting wear and tear, maintaining precision, and reducing the risk of defects in the final product. Good material saves you money in the long run.

Okay, so let’s talk about mold materials. It is like building a house. You need a strong foundation to withstand the elements. Molds are the same. You need a robust material that can handle constant use.

Here’s a breakdown to consider:

| Material | Pros | Cons | Best for |

|---|---|---|---|

| Steel (Various Types) | Durable, wear-resistant, good thermal conductivity, holds tight tolerances, resists corrosion. | Can be expensive, may require heat treatment, heavier than aluminum. | High-volume production, intricate designs, corrosive materials. |

| Aluminum | Lightweight, good thermal conductivity, cheaper than steel, easy to machine. | Less durable than steel, lower wear resistance, may not be suitable for abrasive materials. | Smaller production runs, simple designs, quick prototyping. |

| Other Alloys | Specialized properties (e.g., beryllium copper for high thermal conductivity), can offer unique benefits. | Often expensive, may require specialized machining. | Niche applications with specific performance requirements. |

I remember a time when a customer came to me. They were using a cheap aluminum alloy for their molds. Their molds were constantly breaking down. They switched to a high-grade steel mold. The initial cost was higher. But, the steel molds lasted much longer. This ended up saving them a ton of money in the long run.

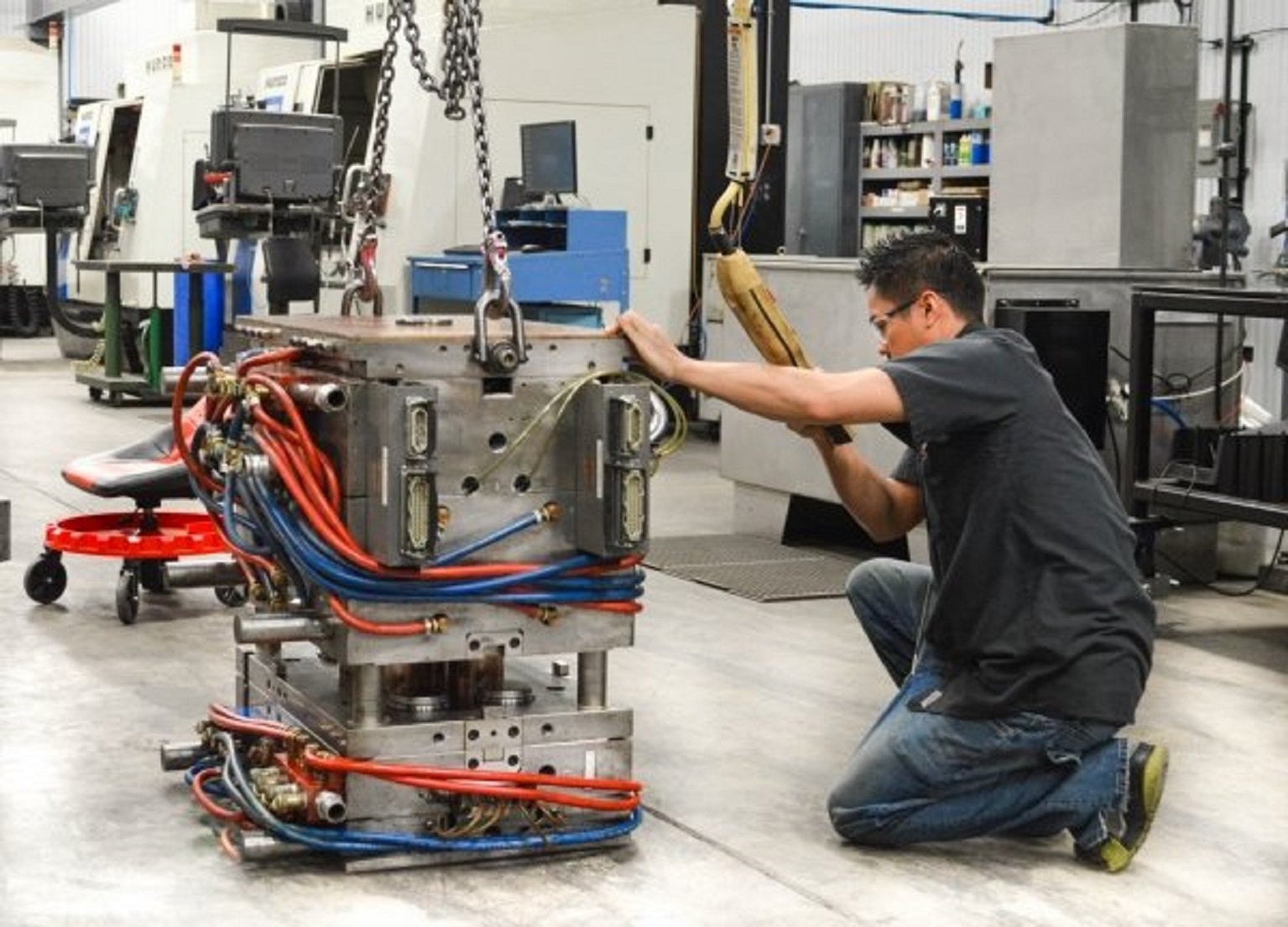

What is the best way to maintain slipper molds to prevent damage?

Are you unsure how to care for your slipper molds? Proper care prevents damage. Taking care of your molds matters.

The best way to maintain slipper molds is through regular cleaning, lubrication, and inspection, addressing minor issues promptly to prevent major damage and extend the mold’s lifespan. Treat your molds well, and they will last longer.

Think of mold maintenance like taking care of a car. You change the oil. You rotate the tires. You do regular check-ups. Molds need the same kind of attention.

Here are the critical steps:

- Regular Cleaning: After each production run, clean the mold thoroughly. Use a soft cloth and appropriate cleaning solutions. Remove any plastic residue or contaminants.

- Lubrication: Keep the mold lubricated with a suitable mold release agent. This reduces friction during the molding process. Friction causes wear.

- Inspection: Regularly inspect the mold for signs of wear, damage, or corrosion. Check for cracks, dents, or deformities.

- Proper Storage: Store molds in a clean, dry environment. Protect them from dust and moisture. Rust is the enemy.

- Temperature Control: Ensure proper temperature control during the molding process. Overheating or rapid cooling can cause stress and damage to the mold.

In my experience, small problems become big problems fast. I once saw a small crack in a mold that was ignored. It quickly grew larger. The entire mold had to be replaced. Regular inspection could have caught that crack early. This would have saved the customer a lot of money.

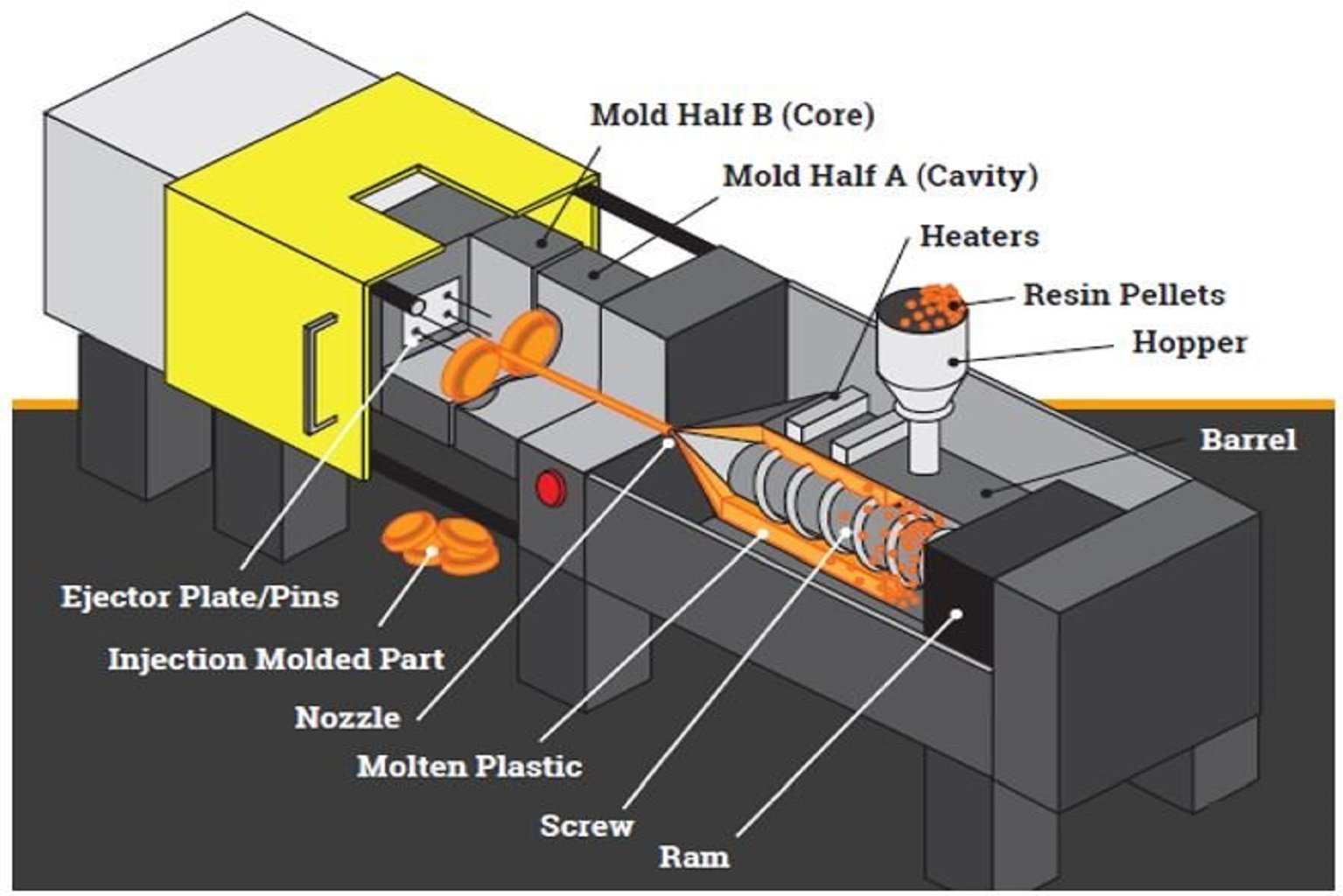

How does optimizing the molding process reduce wear and tear on slipper molds?

Are you curious how the way you mold affects your molds? Optimizing the molding process is key. A well-tuned process is gentle on the molds.

Optimizing the molding process reduces wear and tear by minimizing stress on the mold, ensuring consistent product quality, and preventing damage from excessive pressure or temperature. A smooth process means a long-lasting mold.

Molding is not just about injecting plastic. It is an art and a science. Many factors impact the life of your molds.

Here are some ways to optimize the process:

- Injection Pressure: Control the injection pressure. Too much pressure can damage the mold. Find the sweet spot for quality and mold longevity.

- Cycle Time: Optimize the cycle time. Excessively short cycles can cause thermal stress. Give the mold time to cool properly.

- Cooling System: Ensure the cooling system is working correctly. Consistent cooling prevents warping and other defects. Warping causes wear.

- Material Flow: Design the mold so that the material flows evenly. Uneven flow causes stress.

- Venting: Proper venting is critical. It prevents air traps, which can lead to imperfections.

I have seen customers struggle with inconsistent product quality. They were using outdated molding equipment. They weren’t monitoring the process closely. I helped them upgrade their equipment and optimize their settings. This resulted in better quality products. The molds also lasted longer. It was a win-win situation.

Conclusion

Take care of your slipper molds by picking the right materials, keeping them clean, and molding wisely to save money in the long run.