Are your feet freezing in the winter? Winter slippers are a must. But how do they stay so warm?

The lining of winter slippers is usually fixed by stitching, gluing, or a combination of both. The choice depends on the materials and the manufacturing process.

It’s crucial to know how the lining is secured. This affects the slipper’s warmth and durability. Keep reading to learn more.

Why does the lining material matter so much?

Do you think all linings are the same? Not at all! The lining makes the slipper warm and comfy.

The lining material determines how well your slippers insulate your feet. A good lining keeps your feet warm and wicks away moisture.

The lining does more than just keep your feet warm. It also affects the slipper’s lifespan. A poorly attached lining can bunch up or tear. This makes the slippers uncomfortable and shortens their life. There are several common types of lining materials, each with its own advantages.

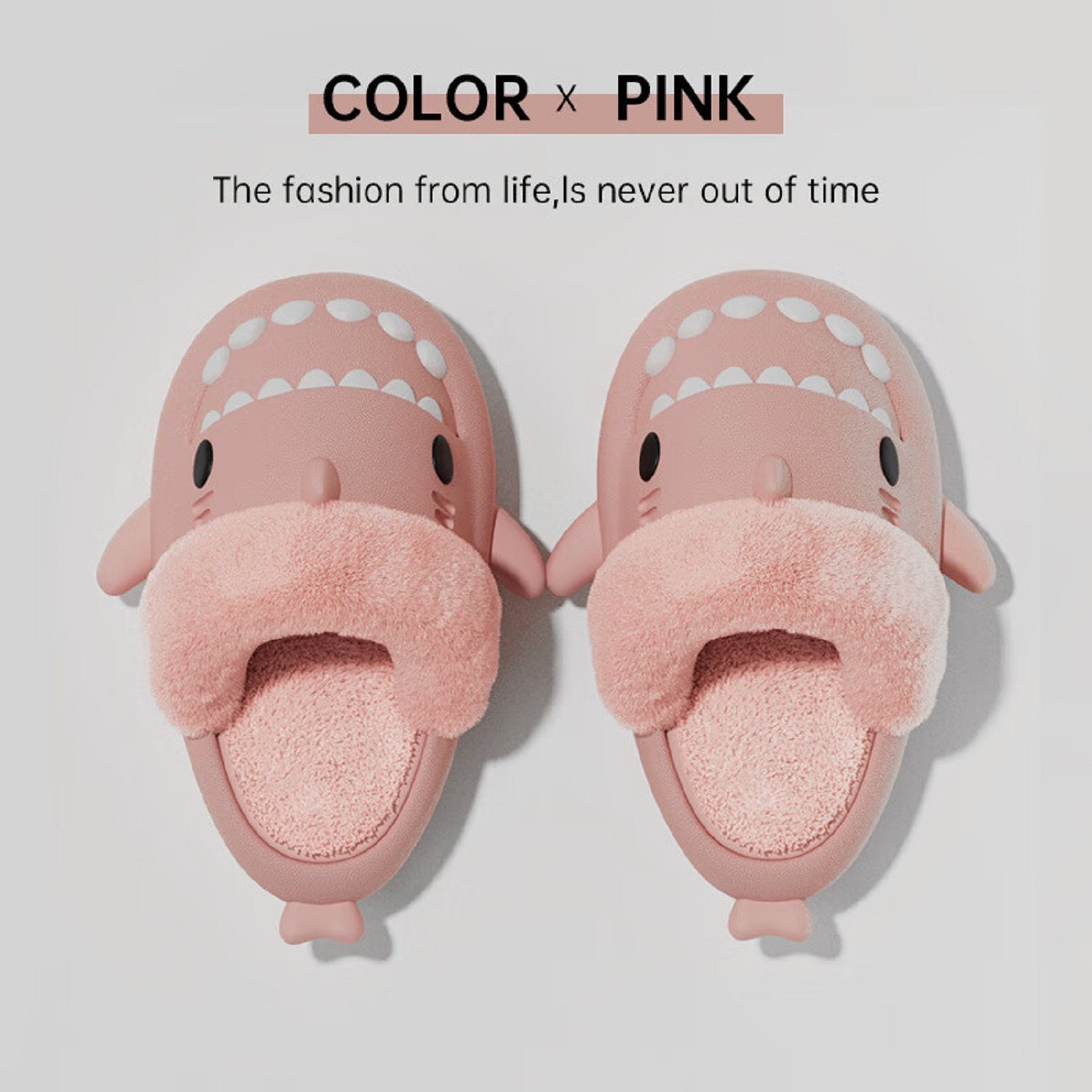

- Faux Fur: This is a popular choice because it’s soft and warm. It’s also relatively inexpensive.

- Wool: Wool is a natural insulator. It’s also breathable, which helps prevent your feet from getting sweaty.

- Sherpa: Sherpa is a type of synthetic fleece. It’s very soft and warm, similar to wool.

- Fleece: Fleece is another synthetic material that is soft and warm. It is also lightweight and dries quickly.

- Cotton: Cotton is a natural fiber that is breathable and comfortable. However, it is not as warm as some other options.

The choice of lining material often depends on the desired warmth, price point, and overall aesthetic of the slipper. I often advise my customers that the best lining material is the one that best meets their needs and preferences.

How does stitching help fix the lining?

Stitching sounds simple, right? But there is more to it. It is a reliable method.

Stitching involves sewing the lining directly to the slipper’s upper material. This creates a strong and durable bond.

Stitching is a common method for securing linings, and here’s why. First, it is durable. A well-stitched lining will last a long time, even with daily wear. Second, it’s flexible. The stitching allows the slipper to bend and move naturally with your foot. Finally, it allows for different design options. We can use different stitch patterns and thread colors to create a unique look.

There are different stitching methods, too. Some methods involve stitching through all layers of the slipper. Others involve stitching the lining to an inner layer. Each method has its own strengths and weaknesses. When we talk with clients about OEM slipper production, we spend a lot of time explaining the different stitching options.

What about glue? How well does that work?

Glue might seem cheap. But new glues are very strong. They can be a great choice.

Gluing involves using adhesives to attach the lining to the slipper. This can be a faster and more cost-effective method than stitching.

Gluing is another popular method for securing linings, and it offers several advantages. It can be faster than stitching. This can reduce production time and cost. It allows for a seamless look. Glue can create a smooth, clean finish without visible stitches. Finally, it’s good for complex shapes. Glue can be used to attach linings to slippers with unusual or intricate designs.

However, there are also some drawbacks to gluing. The bond may not be as strong as stitching. The type of glue used is very important. We must use adhesives that are specifically designed for the materials involved. In my experience, the best results come from using a combination of stitching and gluing. This provides both strength and a clean finish.

Are there other ways to attach the lining?

So, are stitching and gluing all there is? Not quite. We like to use some special methods.

Some manufacturers use molding or specialized fasteners to attach the lining. These methods are less common but can be effective.

While stitching and gluing are the most common methods, other options exist. One such method is molding. This involves shaping the lining material directly onto the slipper using heat and pressure. This creates a seamless and secure bond. Another option is to use specialized fasteners, such as snaps or Velcro. These can be used to attach a removable lining to the slipper. This makes it easy to wash or replace the lining.

These methods are less common because they can be more expensive or require specialized equipment. However, they can be a good option for certain types of slippers. For example, a molded lining might be ideal for a waterproof slipper. I always consider all available options to find the best solution for my customers’ needs.

Conclusion

The lining of winter slippers is fixed by stitching, gluing, or other methods. The best method depends on materials and design.