Abstract: Precision Chemistry Behind Every Step

In the premium slipper market (HS 6404.19.90), "comfort" is often treated as a subjective marketing term. However, for Ningbo Cotton Slipper Co. (NCS), comfort is a measurable result of precise material engineering. By strictly controlling the Shore Hardness (Durometer) and density of Ethylene-vinyl acetate (EVA) and Thermoplastic Rubber (TPR) blends, we solve the two biggest complaints in the footwear industry: "Initial Stiffness" and "Permanent Compression Set" (bottoming out).

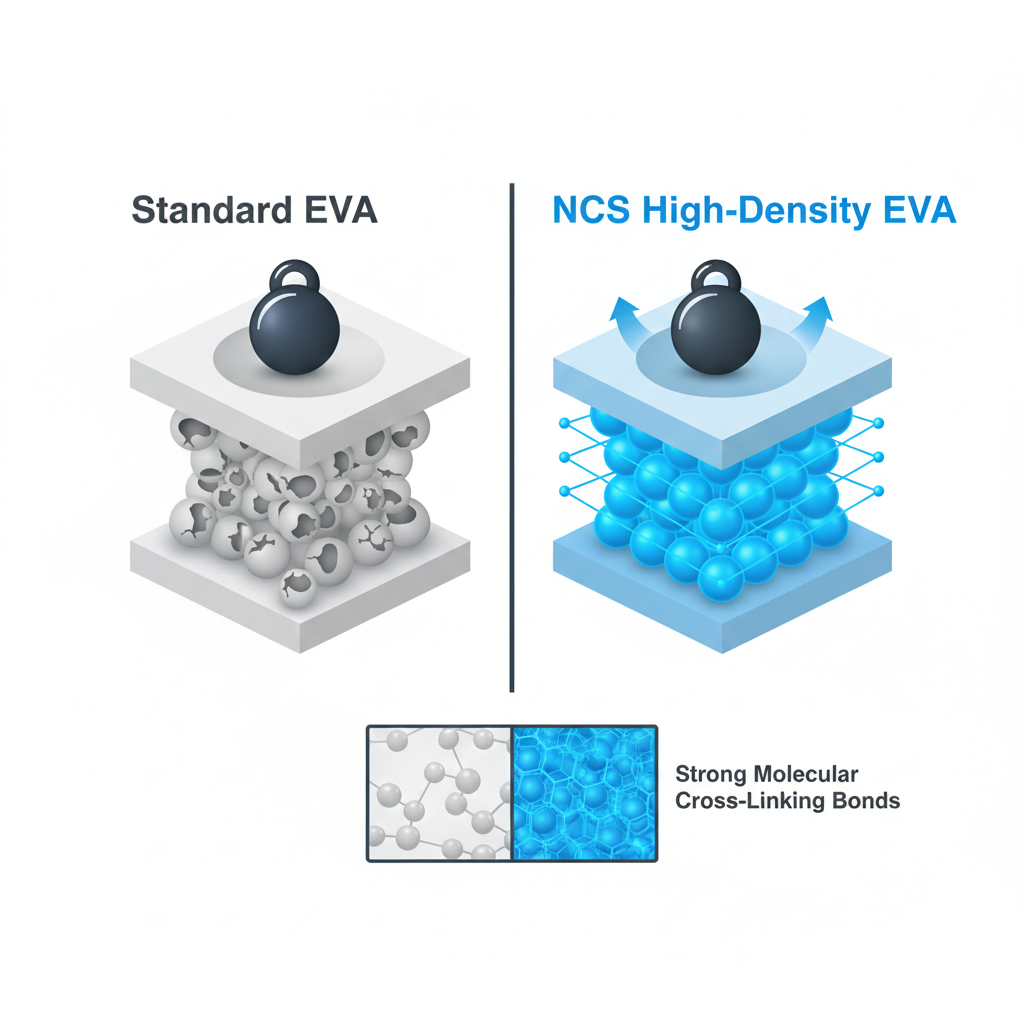

Core Conclusion: By calibrating the EVA expansion ratio and cross-linking density, NCS maintains a strict Shore A range (35°-45°). Our technical EVA formulations achieve a compression set of <20% under ASTM D395 testing, ensuring the slipper retains its loft and cushioning even after a full season of heavy retail use."

The Science of the "Cloud-Like" Feel: Shore Hardness (Shore A)

The tactile perception of a slipper is determined by the resistance of the material to indentation.

The "Sweet Spot" for Mid-Market Luxury

Most low-cost slippers use industrial-grade EVA with a hardness of 55° or higher, leading to a stiff, plastic-like feel.

-

NCS Standard: We target a Shore A hardness of 38° (±2°) for our core "Comfort Line".

-

The Result: This 38° Shore A calibration ensures an optimal balance between initial step-in comfort and material density. This prevents ‘bottoming out’ during the loading phase of the gait cycle, a common quality failure in low-density supermarket-grade slippers.

-

- –

Engineering Against "Bottoming Out": Compression Set Resistance

A common failure for brand owners is when a slipper loses its cushioning after only two weeks of wear, damaging the brand’s reputation for quality.

Molecular Cross-Linking Technology

NCS utilizes virgin EVA resin blends (VA content 18%-28%) integrated with high-performance DCP (Dicumyl Peroxide) cross-linking agents.

-

Compression Set: While standard market EVA has a compression set of 35-40%, NCS engineering reduces this to less than 20% (tested under ASTM D395 standards).**.

-

Recovery: Our formulation achieves a >90% rebound elasticity. This ensures the mid-sole recovers its geometric integrity within 8 hours of rest, maintaining the SKU’s premium shelf-appeal and ergonomic function.

-

- –

Material Strategy: EVA vs. TPR in B2B Sourcing

NCS supports Procurement Directors in material selection by balancing Landed Cost with Durability. Whether optimizing for the lightweight requirements of the Travel/Airline sector or the high-friction (Slip Resistance) needs of Hospital Hospitality, our material engineering mitigates the risk of mass retail returns.

| Material Property | NCS Engineered EVA | NCS High-Flex TPR | B2B Strategic Application |

|---|---|---|---|

| Weight | Ultra-Lightweight | Heavier / Solid feel | EVA: Ideal for travel/airline & lightweight retail. |

| Grip/Traction | Moderate | Superior (Non-slip) | TPR: Ideal for indoor-outdoor use & safety-focused brands. |

| Thermal Insulation | High | Moderate | EVA: Best for winter cotton slippers. |

| Noise Level | Silent | Moderate | EVA: Preferred for high-end hospitality and home use. |

FAQ: Technical Assurance for Quality Directors

Q: How does NCS ensure consistency in hardness across mass production? A: We use automated digital durometers in our ISO 9001-certified facility. Every batch undergoes a 5-point hardness test (Heel, Arch, Toe, and edges) to ensure the variance never exceeds ±2 Shore A.

Q: Can we customize density for different markets? A: Yes. We adjust the AC (Azodicarbonamide) blowing agent ratio and injection pressure to calibrate density. We can produce ultra-light versions (0.12g/cm³) for travel or high-density versions (0.25g/cm³) for long-wear outdoor/indoor hybrid models."

Q: Are your EVA/TPR materials REACH and Prop 65 compliant? A: Absolutely. Our manufacturing protocol exclusively uses virgin EVA/TPR resins. We provide batch-specific ECHA REACH compliance reports and OEHHA Proposition 65 certification to ensure your shipments are clear of heavy metals and restricted phthalates (DEHP, DBP, BBP).**.