Abstract: The Myth of the "Perfect" Factory

In the complex ecosystem of high-volume footwear manufacturing (HS 6404.19.90), claims of "zero defects" are often a marketing facade. For sophisticated B2B buyers, The industry benchmark for a Tier-1 supplier is the Mean Time to Recovery (MTTR) and the robustness of the CAPA (Corrective and Preventive Action) framework.

Ningbo Cotton Slipper Co. Ltd.(NCS) utilizes a formal Root Cause Analysis (RCA) . We treat production deviations as Data Points for System Hardening, ensuring that every technical variance is documented in our Knowledge Management System (KMS) to prevent recurrence across future ODM cycles.. By sharing these findings transparently with our partners, we move beyond the "Blame Game" and toward Continuous Improvement. This case study outlines how our digital monitoring and material science work together to ensure that a mistake made once is never made again.

Core Conclusion: Strategic trust is established through Technical Candor . The NCS RCA framework provides the Digital Chain of Custody necessary to isolate batches, protecting the Landed Margin of our global partners from the systemic risks of unaddressed manufacturing defects.

Case Study: The "Midsole Compression" Deviation

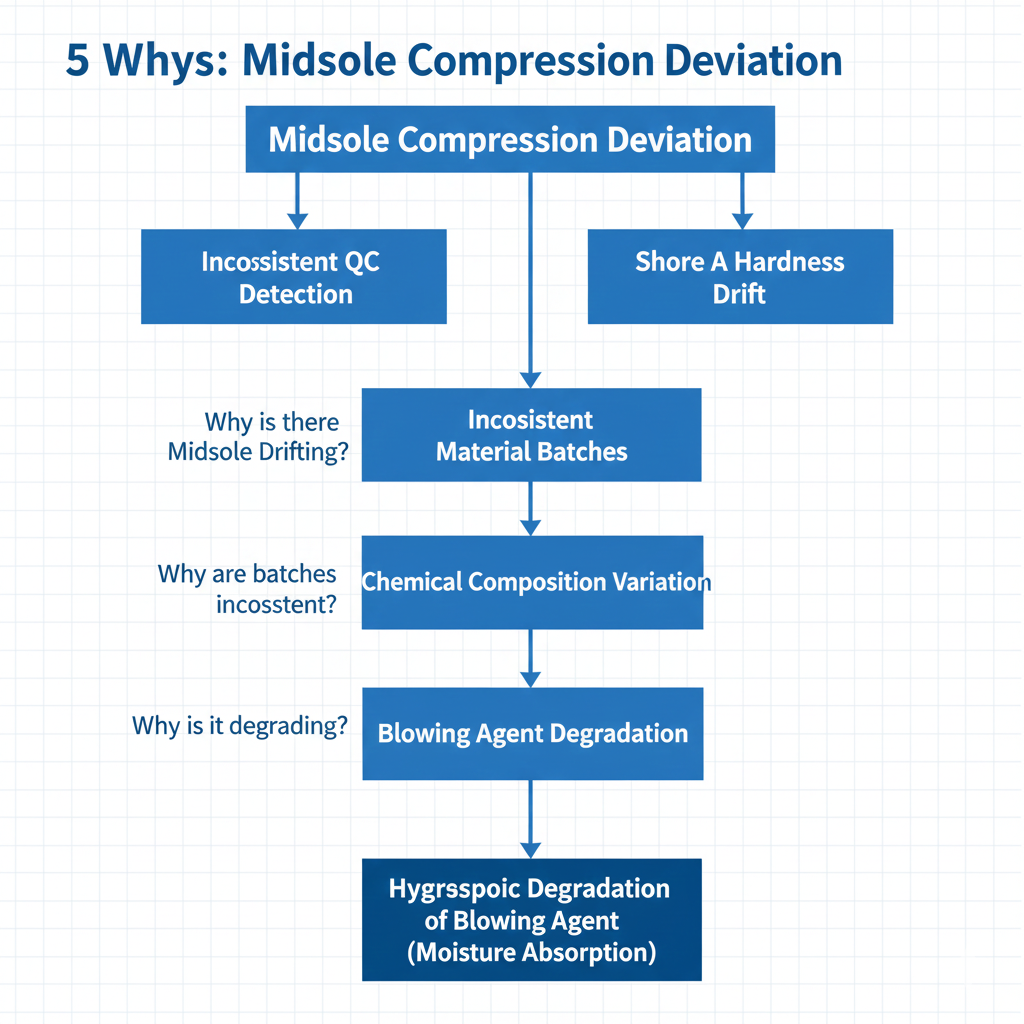

Instead of simply replacing the batch, the NCS engineering team initiated a formal RCA:

Symptom: The EVA midsole was losing height faster than the approved sample.

Detection: A calibrated Digital Durometer Audit (ASTM D2240) revealed a mean deviation in the cross-section of the midsole. The 38° Shore A benchmark had drifted to 32°, indicating a failure in the polymer’s structural modulus.

Root Cause: The investigation identified Hygroscopic Degradation of the chemical blowing agent. Fluctuations in relative humidity within the Tier-2 storage zone compromised the exothermic reaction during the EVA injection process, leading to inconsistent cell-structure density.

Corrective Action: Engineering the Solution

Transparency means nothing without a fix. Based on the RCA, NCS implemented the following:

-

Climate-Controlled Storage: NCS implemented Atmospheric Stabilization Protocols in our chemical mixing zones. By installing sensor-monitored dehumidification systems, we maintain a constant RH (Relative Humidity) of <45%, ensuring the blowing agents retain their chemical potency regardless of external climate shifts.

-

Pre-Production Hardness Calibration: We now perform a "Sample Batch" hardness test for every 5,000 pairs, ensuring the 38° Shore A target is locked in regardless of external weather conditions.

-

Compliance Documentation Update: The RCA report was added to the client’s Compliance Pack, demonstrating to their internal stakeholders that the issue was identified and permanently resolved.

-

- –

Strategic Value of Non-Conformance Reporting (NCR)"

For a Category Manager, receiving an RCA report from NCS provides several strategic benefits:

| Strategic Benefit | How NCS Delivers | Impact on Buyer |

|---|---|---|

| Risk Mitigation | Identification of specific failure points. | Prevents mass recalls and retail returns. |

| Audit Readiness | Formal documentation for ISO 9001. | Satisfies internal corporate governance. |

| Brand Resilience | Proactive communication before shipping. | Protects the brand’s reputation for quality. |

| Data-Driven Trust | Hard data replaces vague promises. | Simplifies the annual vendor review process. |

FAQ: Quality Assurance & Transparency

Q: Does NCS charge extra for formal RCA reporting? A: No. Our Compliance as a Service (CaaS) framework includes full transparency on quality metrics and anomaly reports as a standard feature.

Q: How does this help US Lifestyle Brands? A: For brands with high consumer visibility, an RCA proves you have a "responsible" supply chain. If a consumer questions a batch, you have the data to prove it was an isolated incident that has been engineered out of future production.

Q: Can we see the real-time quality data for our order? A: Yes. Strategic partners can request access to a customized view of our Digital Quality Dashboard, allowing for "Virtual Oversight" from their home office.