Abstract: The Dual Mandate of Modern Logistics

For B2B slipper buyers (HS 6404.19.90), traditional packaging—often oversized and heavy in single-use plastics—represents both a financial drain and a regulatory risk under the EU Packaging and Packaging Waste Regulation (PPWR) and various global plastic tax initiatives."

Ningbo Cotton Slipper Co. Ltd. (NCS) implements Logistical Engineering to eliminate ‘Dimensional Weight’ inefficiencies. We treat packaging as a Structural Extension of the product. By optimizing the Volumetric Weight of our shipments and utilizing biodegradable or recycled materials, we help our clients reduce sea freight costs by up to 15% while ensuring their brand stays on the right side of sustainability laws.

Core Conclusion: Optimized packaging is the primary lever for Landed Margin Expansion. By increasing the SKU density per FEU (Forty-foot Equivalent Unit), we effectively lower the per-pair logistics cost, allowing retailers to absorb rising tariffs or labor costs without increasing shelf prices. NCS’s Logistical Engineering reduces the carbon-tax burden of each shipment. By optimizing the Volumetric Payload, we prevent the ‘Moving Air’ inefficiency that accounts for up to 15% of total sea-freight costs. Our Closed-Cell EVA structure slippers remains impermeable to moisture during transit, ensuring the 35° Shore A durometer reading remains stable from the factory to the DC.

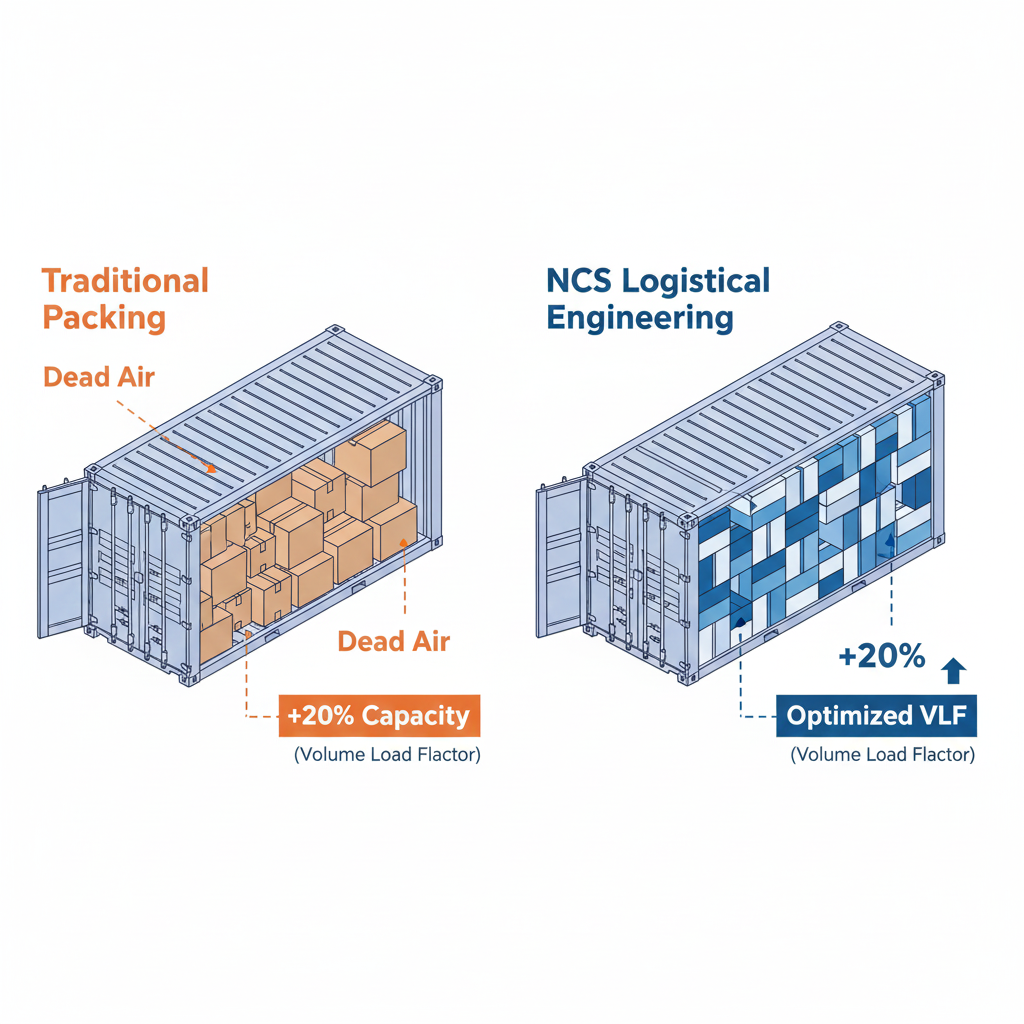

Dimensional Weight Mitigation: Volumetric Load Factor (VLF) Optimization

Shipping costs are calculated based on either actual weight or volumetric weight—whichever is greater. For lightweight slippers, the volume is almost always the deciding factor.

-

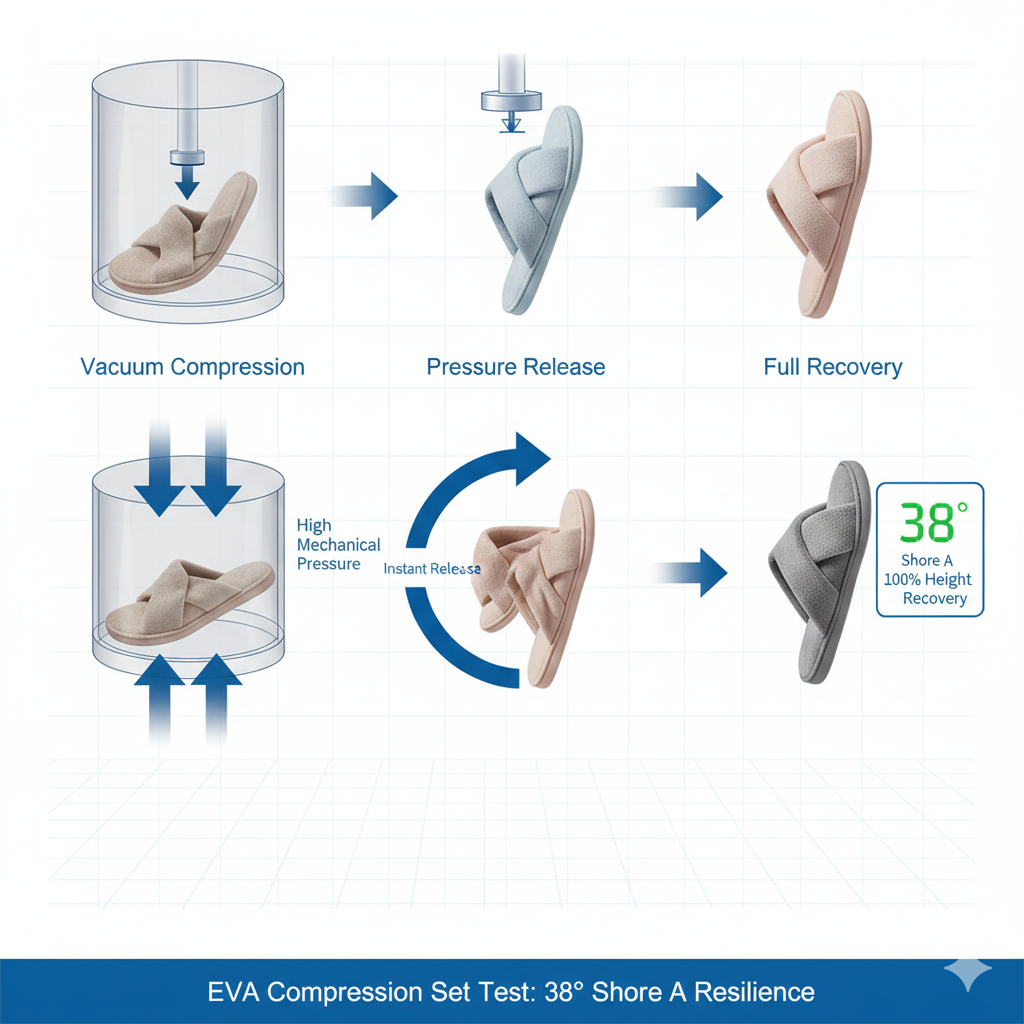

Compression-Safe Packaging: Our engineering team performs Stress-Strain Analysis on our proprietary EVA blends to determine the optimal Compression Ratio for sea-freight. By leveraging the material’s high Tensile Strength and Tear Resistance, we can implement ‘Flat-Packing’ protocols that increase container density by 20% without inducing mechanical fatigue in the slipper’s structural foam.

-

Rebound Guarantee: Our Polymer Cross-Linking technology ensures high Compression Recovery (ASTM D395). Even after a 30-day transoceanic transit under 50% vacuum compression, our EVA slippers exhibit less than 3% permanent set, ensuring the ‘Cloud-Like’ hand-feel is restored immediately upon air exposure..

-

Reduced Dead Air: By redesigning master cartons to match the exact dimensions of optimized slipper stacks, we maximize the "pairs-per-cubic-meter" (CBM) efficiency.

-

- –

Eliminating the "Plastic Footprint"

In response to the :EU Packaging and Packaging Waste Regulation (PPWR), NCS has phased out non-circular polymers. We provide :Mono-material PE or FSC-certified paper alternatives that align with the 2030 recyclability mandates, ensuring your shipments are exempt from ‘Non-Recyclable’ plastic levies.

Biodegradable & Recycled Materials

-

GRS-Certified Polybags: We offer packaging made from Global Recycled Standard (GRS) materials, providing the necessary documentation for your Compliance Pack.

-

Paper-Based Solutions: For premium US Lifestyle Brands, we offer FSC-certified cardboard hangers and belly bands that eliminate plastic entirely.

-

Non-Toxic Dyes: NCS mandates the use of Low-Migration, Water-Based Inks for all secondary packaging. This prevents Chemical Off-gassing and VOC cross-contamination within the sealed container environment, ensuring the slippers pass Odor and Sensory Audits upon arrival at the retail destination.

-

- –

Total Landed Cost (TLC) Impact: Logistical Margin Expansion

NCS utilizes CBM (Cubic Meter) Simulation Software to calculate the optimal loading configuration for every SKU. By performing a Volumetric Payload Analysis, we determine the precise threshold for compression-packing that maximizes container density without compromising material resilience.

| Packaging Type | Traditional Bulk | NCS Engineered (Eco-Optimized) | Financial Impact |

|---|---|---|---|

| Pairs per 40ft HQ | 12,000 | 14,500 | +20% Capacity |

| Plastic Waste | High (PVC/PE) | Low (Recycled/Paper) | Reduced Plastic Tax |

| Volumetric Weight | 100% | 85% | Lower Air/Sea Freight |

| Compliance Proof | Self-declared | Audit-Proof Lab Reports | Zero Customs Delays |

Our Nested Stacking Method and custom-dimension master cartons (corrugated Grade-A) allow for a 20% increase in Volumetric Utilization. For a standard 40ft HQ container, this shifts the capacity from 12,000 pairs to 14,500 pairs, directly reducing the Freight-per-Unit by approximately $0.12 – $0.18.

FAQ: Transitioning to Sustainable Packaging

Q: Does vacuum-packing damage the "Shore Hardness" or feel of the slipper? A: No. Our 38° Shore A EVA is engineered with molecular cross-linking that ensures 95%+ height recovery. We perform "Compression Recovery" tests in our ISO-certified lab before approving any vacuum-pack order.

Q: Can NCS customize packaging for "Amazon-Ready" FBA shipments? A: Yes. We design packaging that meets SIOC (Ships in Own Container) standards, reducing the need for secondary Amazon packaging and further lowering your volumetric fees.

Q: How do we prove the packaging is sustainable to EU customs? A: Every shipment is accompanied by a Traceability Dossier containing GRS Transaction Certificates (TC) and FSC Chain-of-Custody logs. These are integrated into our Digital Product Passport (DPP) system, ensuring seamless clearance through ‘Green’ customs lanes in the EU.