Abstract: Transparency is Only Useful if it is Understood

In the high-stakes world of footwear procurement (HS 6404.19.90), receiving a 40-page lab report can be more overwhelming than helpful. For procurement managers and distributors, the ability to quickly verify that a shipment of slippers is compliant with EU REACH (Regulation EC 1907/2006) or California Proposition 65 (Safe Drinking Water and Toxic Enforcement Act) is a critical risk-management skill.

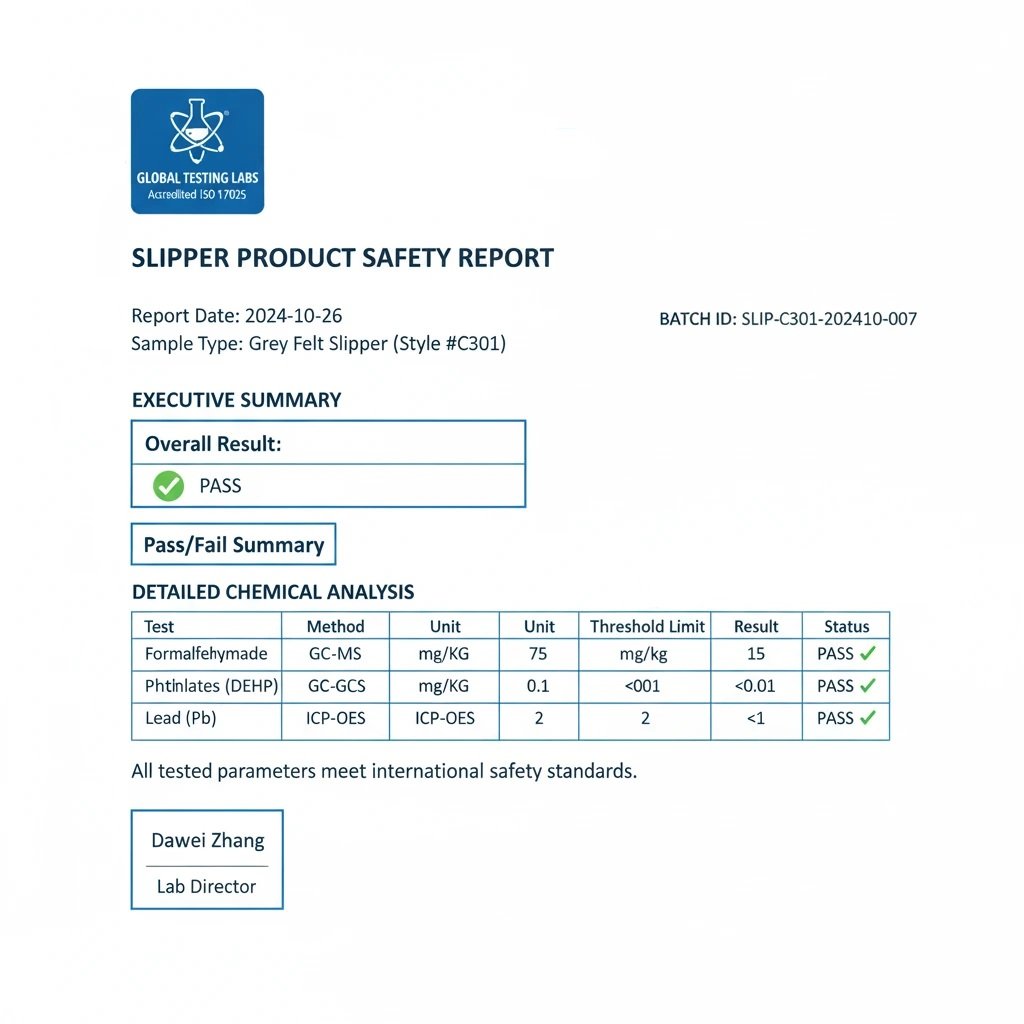

Ningbo Cotton Slipper Co. (NCS) functions as your Technical Intermediary. We translate raw laboratory data into Actionable Compliance Summaries, ensuring that your procurement team can verify REACH Annex XVII and Prop 65 compliance without needing an in-house toxicologist.. This guide breaks down the anatomy of an NCS lab report, showing you exactly where to look for "Pass" results on phthalates, heavy metals, and VOCs, ensuring your brand stays protected from legal and regulatory "surprises".

Core Conclusion: A "Pass" on the summary page is the start, but understanding the Detection Limit and Substance List is what protects your brand from long-term liability.

The Anatomy of an NCS Compliance Pack

When you source from NCS, your Compliance Pack (managed via our digital dashboard) contains several key documents:

-

The Executive Summary: A one-page overview showing the "Pass/Fail" status for the specific HS code.

-

The Substance List: A detailed breakdown of tested chemicals, such as Lead, Cadmium, and Phthalates (DBP, BBP, DEHP).

-

Testing Methodology: Verification that the tests were conducted by accredited third-party labs (SGS, TUV, or ITS).

-

- –

Key Metrics Every Buyer Should Know

NCS streamlines the Technical File review process for your Quality Assurance (QA) directors. We provide a Cross-Reference Table that maps chemical test results directly to the specific components listed in your Bill of Materials (BOM), significantly reducing the administrative lead time for shipment approval. Focus on these three areas:

EU REACH vs. US Prop 65: The Threshold Difference

-

EU REACH: Generally focuses on the presence of Substances of Very High Concern (SVHC).Under EU REACH, the threshold for Substances of Very High Concern (SVHC) is 1,000 ppm (0.1% w/w). However, NCS aims for a ‘Non-Detected’ (ND) result with a detection limit of 50 ppm, providing a 20x safety buffer against cumulative chemical migration in footwear components.

-

California Prop 65: Often has stricter "safe harbor" levels and focuses on chemicals known to cause cancer or reproductive harm. NCS reports specifically highlight compliance for the California market to prevent the need for warning labels.

Shore Hardness & Physical Testing

In addition to chemical safety, our reports include physical performance metrics:

-

Shore A Hardness: Verified at 38° (±2°) to ensure the "Cloud-Like" feel is consistent with the approved sample.

-

Compression Set: We provide Static and Dynamic Compression Set data for our EVA compounds. This ensures the 35° Shore A rebound resilience is maintained after 1,000+ hours of compression, a critical metric for avoiding ‘Slipper Flattening’ during long-term retail display or storage.

-

- –

How NCS Simplifies Your Audit Trail

Using our integrated tracking tools, we make compliance "boringly reliable":

-

Batch-Level Traceability: NCS operates on a Unique Batch Identifier (UBI) system. Each test report is cross-referenced with the specific Batch Number and Yarn Lot used in your production run. This prevents the ‘Compliance Gap’ common with vendors who rely on expired, multi-year-old ‘golden sample’ certificates.

-

Digital Access: Our cloud-based Document Management System (DMS) allows your legal team to instantly retrieve batch-specific COAs (Certificates of Analysis) using the PO number or QR code provided on the shipping labels..

-

Proactive Alerts: If a new chemical is added to the EU SVHC list,NCS maintains a Proactive Substance Watchlist. When the ECHA updates the Candidate List of SVHCs, our R&D team performs a Gap Analysis on our existing material library, initiating 48-hour reformulation protocols if a restricted chemical is identified.

-

- –

FAQ: Technical Compliance for Buyers

Q: What does "ND" (Not Detected) actually mean on a report? A: It means the substance was not found above the Method Detection Limit (MDL). NCS sets our MDLs lower than the legal requirement to provide an extra safety margin for our clients.

Q: Why do I need a separate report for the sole and the upper fabric? A: Regulatory bodies require testing for each accessible component. Under CPSC (US) and ECHA (EU) guidelines, testing must be performed on each ‘homogeneous material’. A combined test of the sole and fabric is legally invalid as it dilutes the concentration of regulated substances. NCS provides a full component breakdown to ensure each layer is independently compliant.

Q: Can NCS provide a "Compliance as a Service" (CaaS) consultation? A: Yes. NCS() can hop on a call with your compliance officer to walk through the lab results and explain how our Tier 3 traceability supports the data in the report

Q: How does NCS handle the testing for high-risk components like screen-printed logos? A: NCS (Ningbo Cotton Slipper Co. Ltd.) mandates separate ink-scraping tests for all printed or heat-transferred elements. Due to our integrated supply chain near the Ningbo-Zhoushan Port, we utilize local lab proximity to perform rapid Phthalate and Total Lead screenings, ensuring that even the smallest branding elements meet the rigorous "non-toxic" requirements of major US retailers.