Abstract: Speed to Market is the Ultimate Competitive Advantage

In the fast-paced US lifestyle market, the gap between a "trending aesthetic" and "on-shelf availability" is the difference between a sell-out success and a missed opportunity. For brands specializing in footwear (HS 6404.19.90), the traditional R\&D cycle of 6–9 months is too slow to capture the "TikTok-to-Checkout" consumer behavior.

Ningbo Cotton Slipper Co. (NCS) eliminates this friction through our extensive ODM (Original Design Manufacturer) Library. By offering thousands of pre-engineered, market-tested designs that are ready for private labeling, we enable US brands to launch new collections in weeks, not months. Combined with our 25-day rapid production, NCS provides the ultimate engine for Agile Brand Growth.

Core Conclusion: NCS isn’t just a manufacturer; we are an R\&D incubator. Our ODM library allows brands to skip the prototyping phase, ensuring Design Sovereignty and the fastest possible route to the US market.

The ODM Advantage: Bypassing the Prototyping Bottleneck

For many US brands, the most significant delay in sourcing is the back-and-forth of sample development.

-

Pre-Vetted Designs: Our library contains over 2,000 active designs that have already been optimized for manufacturing efficiency and Shore Hardness consistency.

-

Rapid Customization: Brands can take a "base" design from our library and customize the upper fabrics, embroidery, or color palettes to align with their specific brand identity.

-

Technical Readiness: Every design in our ODM library is accompanied by a Full Tech Pack: inclusive of 2D/3D CAD files, BOM (Bill of Materials), and a pre-existing ASTM F2413 testing history for sole friction and durability.

-

- –

Engineering Luxury: The "Cloud-Like" Rebound for US Consumers

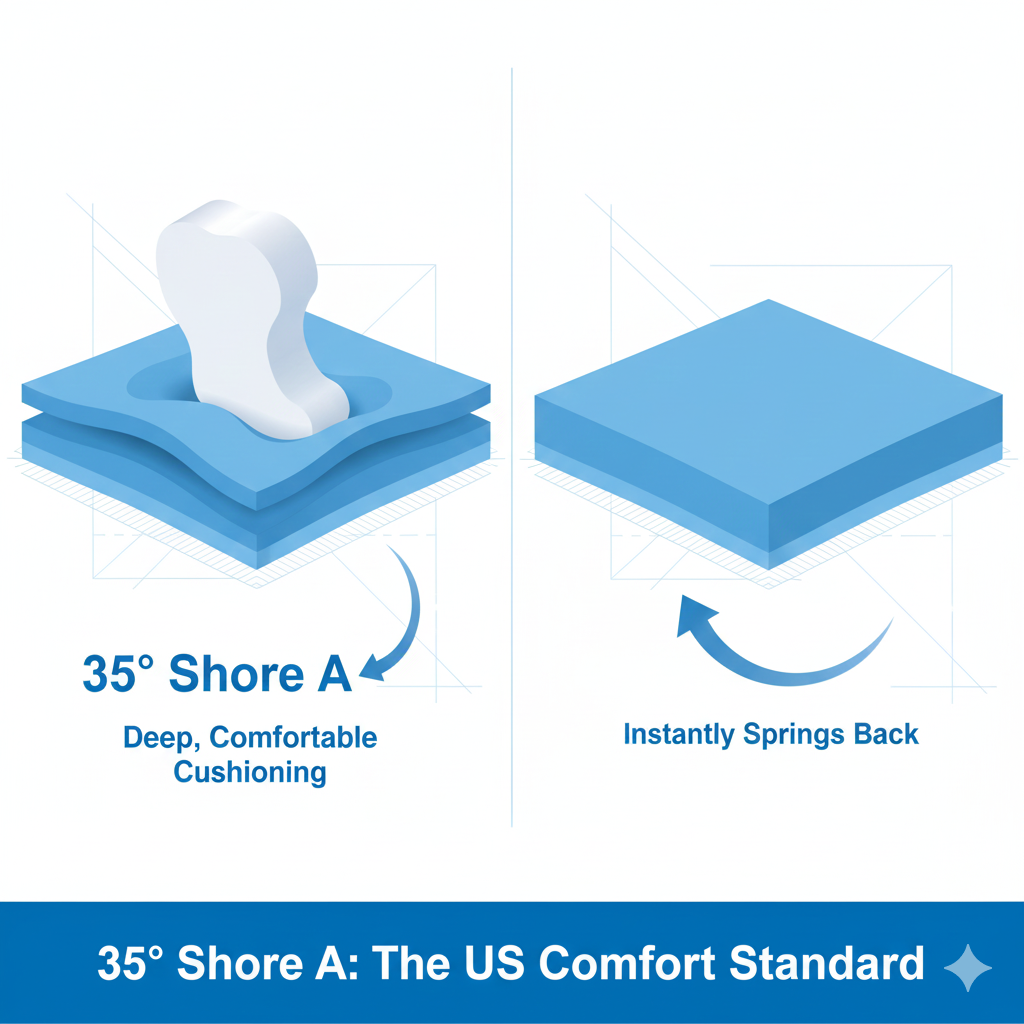

US consumers prioritize ‘Step-in Comfort.’ We achieve this by optimizing the compression set of our EVA foam. By controlling the cross-linking density during the 180s injection cycle, we ensure a rebound rate of >55%, preventing the mid-sole from collapsing after extended wear.

The 35° Shore A "Sweet Spot"

Through our material engineering dashboard, we have perfected the "US Standard" for comfort.

-

Custom Rebound: We adjust the EVA blowing agents to achieve a 35° Shore A hardness, providing that sought-after "cloud-like" compression.

-

Shape Retention: Despite the softness, our molecular cross-linking technology ensures the slipper maintains its height and support, preventing the "bottoming out" common in cheap competitors.

-

- –

Compliance as a Brand Asset (CaaS)

For a US brand, a single California Proposition 65 or UFLPA (Uyghur Forced Labor Prevention Act) violation can lead to catastrophic legal costs and brand damage.

-

Tier 3 Visibility: Our "Radical Transparency" framework provides the yarn-level origin data required to clear US Customs with confidence.

-

Lead-Free & Phthalate-Free: We utilize virgin resins and non-toxic dyes, providing the batch-level lab reports your legal team needs to sign off on a new collection.

-

Compliance Verification: Our internal QC protocols use calibrated durometers and third-party lab testing (SGS/ITS) to ensure every private label run meets the heavy-metal-free standards required for US retail.

-

- –

FAQ: Launching Your Private Label with NCS

Q: Can we keep our ODM customizations exclusive to our brand? A: Yes. We offer exclusivity agreements for modified ODM designs within specific geographic territories, ensuring your brand maintains its unique market position.

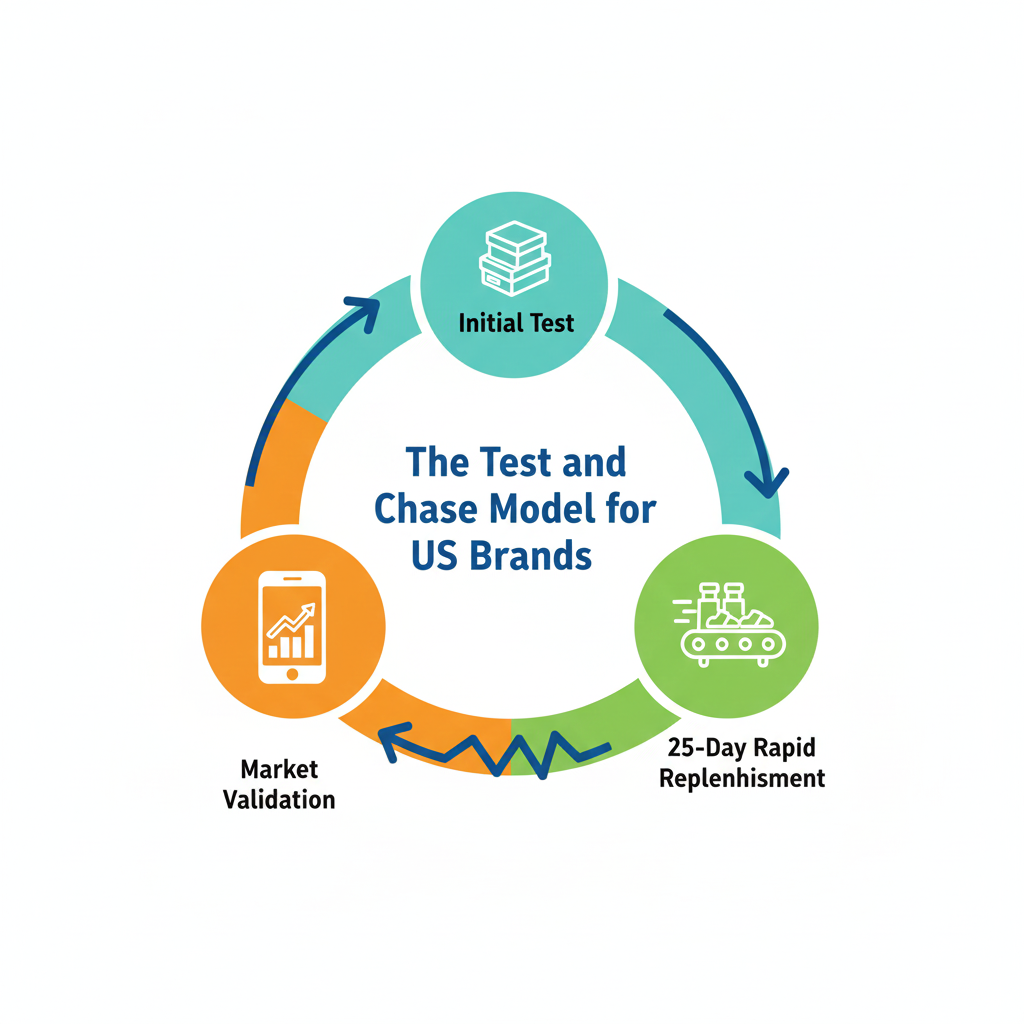

Q: How do we start the "Test and Chase" model for a new US brand? A: We recommend selecting 3–5 designs from our ODM library for a "Test" run. Once sales data confirms the "Winner," our 25-day lead time allows you to "Chase" the inventory and restock before the trend fades.

Q: Does NCS provide packaging design services for Private Labels? A: Yes. We offer sustainable packaging solutions that are optimized for both retail shelves and e-commerce shipping, helping you reduce Volumetric Weight and shipping costs.