The production process of making cotton slipper is a cornerstone in the footwear industry. As someone who knows how to do this, I’m going to walk you through the process step-by-step. I’ll show you the techniques and the principles you need to know to make a high-quality product.

Material Preparation for Cotton Slippers

The basis of any good product is the selection and preparation of your materials. Cotton slippers are no different.

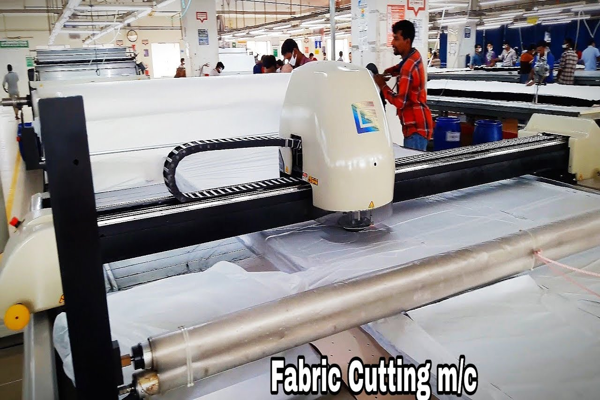

- Fabric Selection and Cutting:

The first thing you do is pick out the fabric. You need to use the right fabrics like cotton or plush that are comfortable, durable, and breathable. The fabric you choose needs to look good and work well for the design you’re creating. For the soles, you use EVA or rubber because they are flexible and non-slip

Once you have your materials, you have to cut them. You use a cutting machine or templates to cut the fabric and the soles to the correct shapes. This ensures consistency and minimizes waste.

Shoe Upper Construction

With the materials prepared, the next step is crafting the shoe upper—the part of the slipper that wraps the foot.

- Sewing Techniques:

This is where you need a lot of skill. You take the cut pieces and sew them together using industrial sewing machines to create the basic upper. This is where you have to pay attention to the details. You don’t want any loose threads or any seams that are not lined up because that will affect the quality of the product.

Reinforced stitching is often applied to areas that experience frequent stress, such as the toe box or sides of the slippers.

- Inner Lining and Padding:

Adding a soft lining to cotton slippers ensures comfort and durability. This could be something like fleece or padded foam that makes them soft and warm. Padding is evenly distributed to keep the slippers from getting lumpy and to maintain their shape.

Sole Processing and Anti-Slip Features

The sole is a big deal. It’s the part that makes the slipper last a long time and keeps you from getting hurt.

- Sole Cutting and Shaping:

Sole materials, usually EVA or rubber, are cut to the right size using die-cutting or laser-cutting machines. Each sole has to line up perfectly with the upper so they can be put together later.

- Anti-Slip Coating and Design:

Safety is a big deal when it comes to making slippers, especially for indoor use. You don’t want people to fall down. The anti-slip properties are added to the sole through special coatings or textured patterns. These patterns are often molded into the sole during the cutting process to give you more traction on smooth surfaces like tile or hardwood floors.

Assembly of Upper and Sole

Once you have the upper and the sole ready, you start putting them together.

- Adhesion Techniques:

Gluing is the most common way to attach the upper to the sole. You use good hot-melt or water-based adhesives on both pieces. You line up the upper with the sole, then you put pressure on it to make the glue stick. - Stitching Reinforcement:

To make them last longer, many manufacturers sew the upper to the sole after they glue them.This ensures that the slippers manufacturing process results in a durable product

Quality Control and Packaging

The last step in the process is to make sure every pair of slippers meets the quality standards.

- Appearance Inspection:

Every slipper goes through a visual inspection to make sure there are no defects like crooked stitching, discoloration, or glue marks. - Structural Testing:

Tests are done to make sure the sole is stuck on good, the slipper is flexible, and the anti-slip stuff works. If they don’t pass these tests, they don’t go down the line. - Cleaning and Packaging:

Before they package them, they clean them up to get rid of all the dust and crap from the manufacturing process. Then they package them the way you want them packaged, whether it’s in a simple plastic bag, a paper bag, or a fancy gift box.

2. Conclusion

The production of cotton slippers is a perfect example of the marriage of craftsmanship and technology. From the selection of materials to the way they put them together, every step is designed to create a product that’s comfortable, lasts a long time, and looks good. By paying attention to quality control and the little things, manufacturers can make sure they keep their customers happy and their reputation strong in a competitive market.

If you want to read more about production, click this article to get more feelings – 5 Key Steps in the Slipper Production Process