Choosing the right slipper supplier is one of the most important decisions you’ll make if you’re in the footwear business. Whether you’re a retailer, wholesaler, or brand owner, your supplier will determine your costs, the quality of your product, and your customers’ happiness. I’ve worked with many businesses to help them optimize their supplier networks. I know the ins and outs of this process. In this article, I’m going to share with you six key factors to consider when choosing a slipper supplier.

Product Quality

Let’s start with the most important thing, quality. A supplier who doesn’t deliver quality can ruin your brand and your customers’ trust. To avoid this, always:

- Ask For Quality Documentation: Ask for detailed production and quality control reports. Good suppliers will have certificates like ISO, CPSIA (for North America), or REACH (for the EU).

- Test Samples Thoroughly: Don’t just look at how pretty they are. Test them for durability, comfort, and material safety. Create a checklist for evaluating your samples. Look at things like wear resistance, ergonomic design, and eco-friendliness.

Pro Tip: Use a third-party inspection agency to verify that the final product matches the sample quality. Below are most famous agency globally.

| Testing Agency | Applicable Scope |

| SGS | Textiles, footwear, food, electronics |

| TÜV Rheinland | Industrial products, footwear, textiles |

| Intertek | Footwear, apparel, electronics, food |

| BV (Bureau Veritas) | Footwear, apparel, toys, electronics |

| UL (Underwriters Laboratories) | Electronics, footwear, textiles |

| QIMA (Asiainspection) | Footwear, textiles, electronics, toys |

| ITS (Industrial Testing Services) | Footwear, textiles, chemicals |

| CMA Testing | Footwear, textiles, toys |

Pricing and Cost

Price isn’t everything, but hidden costs can kill your margins. A good supplier will be transparent about all costs, including the price of the product, shipping costs, and tariffs. Here’s how you can manage your costs:

- Break Down the Total Cost: Always ask for an itemized quote that shows the unit price, transportation, and any additional charges. This will help you catch hidden fees.

- Negotiate Strategically: Use volume or long-term contracts to get discounts. Also, ask about tiered pricing for larger order quantities.

Pro Tip: Calculate the total cost of ownership (TCO) using this formula:

Total Cost = Unit Price × Quantity + Shipping Costs + Tariffs + Extra Service Fees.

This approach ensures you’re evaluating the full financial impact.

Reliability and Delivery

A supplier might have the right price and the right product, but if they can’t deliver on time, you’re screwed. To evaluate a supplier’s reliability:

- Request Historical Data: Ask for their on-time delivery (OTD) rate for the past year. A rate above 95% is a good benchmark for reliable suppliers.

- Check Production Capacity: Make sure they can ramp up production if you need more or need it faster. This includes having backup production lines or enough raw materials on hand.

Pro Tip: Mitigate your risk by having a service-level agreement (SLA) that includes penalties for late deliveries. This will make sure your orders are a priority for them.

Customization

Customization is a game-changer, especially if you’re building a private label or trying to differentiate yourself in a competitive market. Not all suppliers can handle custom orders well. Here’s how to make sure they can:

- Assess Their OEM/ODM Capabilities: Make sure they can do full customization including design support, logo printing, and packaging solutions.

- Review Past Projects: Ask for case studies or samples of custom products they’ve done. This will give you confidence they can meet your expectations.

Pro Tip: Protect your intellectual property by signing a Non-Disclosure Agreement (NDA) with your supplier before sharing any proprietary designs.

Transparency and Sustainability

Consumers today are more interested in sustainable and ethically produced products. Choosing a supplier who is transparent and meets these criteria will not only improve your brand image but also align with global trends.

- Check Their Supply Chain: Ask for documentation on where they get their raw materials and what their labor conditions are like. Platforms like Sedex can help you evaluate ethical compliance.

- Go Green: Many suppliers now offer sustainable materials like recycled TPU or biodegradable packaging. If this is important to your brand, make sure you prioritize these options.

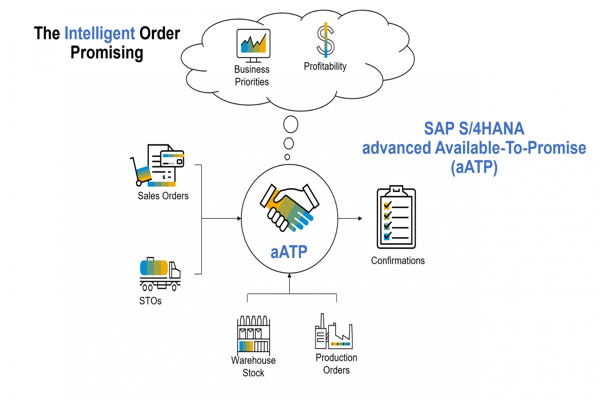

Pro Tip: Adopt supply chain monitoring tools, such as SAP, Oracle to ensure transparency at every stage of production.

After-Sales Support

The relationship with your supplier doesn’t end when they deliver the goods. Strong after-sales support is essential to handle any issues with the product and build a long-term relationship. Here’s what to look for:

- Warranty and Return Policies: Make sure they have a clear policy for defective products. This will help you minimize your losses and build trust.

- Dedicated Account Managers: Having a person at the supplier you can talk to makes communication easier and helps you get issues resolved faster.

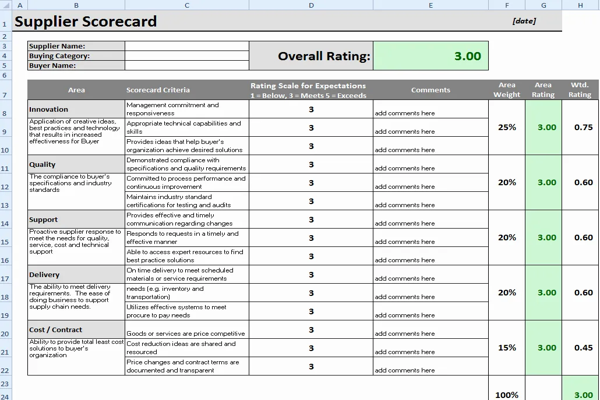

Pro Tip: Regularly evaluate your supplier’s performance using a scorecard. This should include things like how consistent their quality is, how often they deliver on time, and how quickly they respond to you. This will help you see where you need to improve or if you need to keep working with them.

Conclusion

Choosing the rightslipper supplier is more than just comparing prices. You need to find a partner who fits your business, delivers consistent quality, and helps you reach your goals. By focusing on these six things—product quality, price transparency, reliability, customization, supply chain ethics, and after-sales support—you’ll set yourself up for success.

After cleary know the key points for supplier selection, then you can read this article to find some potential vendors-“5 Efficient Ways to Find the Right Slipper Suppliers”