Slipper production may seem straightforward, but anyone involved in procurement and supply chain management knows the reality: every detail matters. From selecting the right materials to ensuring seamless production and delivery, each step presents its own challenges and opportunities. As an industry expert, I’ve laid out the five key steps in slipper production to help you streamline your processes, avoid common pitfalls, and achieve high-quality results efficiently.

Material Selection and Procurement

Selecting the right materials is the foundation of successful slipper production. If you get this step wrong, it doesn’t matter how much you fine-tune things later in the process.

What Are the Best Materials for Slippers?

The most common materials used are EVA, rubber, PU, and PVC. Each has its own strengths.

| Material | Key Features | Best Use Case |

|---|---|---|

| EVA | Lightweight, flexible, cost-effective | Beach slippers |

| Rubber | Durable, slip-resistant | Outdoor use |

| PU | Soft, comfortable | Premium indoor slippers |

| PVC | Affordable, versatile | Mass production |

When planning slipper production, choose materials based on your product’s target use and market segment to ensure efficiency.

How to Identify Reliable Material Suppliers

Working with the right supplier is critical. Here’s how to evaluate them:

- Check Certifications: Look for ISO or other quality standards.

- Request Samples: Test the materials for durability, flexibility, and appearance.

- Assess Reputation: Read reviews, ask for references, or visit their facilities.

Avoiding Common Procurement Pitfalls

Many people who are new to this will fall for the low price without checking the quality. Then they’ll have issues with things like non-compliance or delays. To avoid this:

- Always check certifications, especially for environmental standards like REACH or RoHS.

- Put strict quality and delivery clauses in your contracts.

Mold Design and Manufacturing

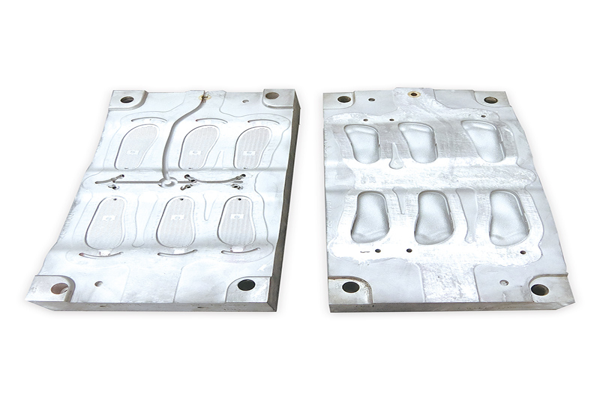

The design and quality of your molds will directly impact the look, feel, and cost of your slippers.

The Role of Mold Design in Slipper Production

Your molds determine the shape and texture of your slippers. Good molds help you produce the same thing over and over again, reducing defects and waste. If you’re making high-end products, you need precision molds.

Tips to Minimize Mold Costs

- Leverage Generic Molds:For standard designs, generic molds save time and money.

- Shared Mold Options: Work with manufacturers who will share molds to help you save money upfront, especially if you’re doing small runs.

Injection Molding and Production

Injection molding is the heart of slipper production. It’s the process of taking your raw materials and turning them into the products your customers love. Understanding this step will help you reduce defects and increase your efficiency.

Key Parameters in Injection Molding

| Parameter | Purpose |

|---|---|

| Temperature | Make sure you heat the materials correctly so they don’t warp or have weak spots. |

| Pressure | You need to make sure you have even pressure so you don’t have air bubbles. |

| Cooling Time | You need to make sure you let them cool down so they don’t get all messed up. |

Regularly monitor and adjust these parameters to ensure consistent quality.

Reducing Defects with Practical Adjustments

Common problems like bubbles, uneven surfaces, or weak bonds are usually caused by your settings being off. Make sure you calibrate your machines regularly and train your operators to recognize and fix these problems quickly.

Assembly and Packaging

Once you have your core slipper components ready, it’s time to put them together and package them. These steps are often what make or break the market appeal of your final product.

Efficient Assembly Methods

| Method | Features |

|---|---|

| Hot Pressing | Fast and efficient, suitable for large-scale production. |

| Cold Gluing | Ensures a clean finish but requires careful application. |

| Stitching | Provides a premium look and feel for high-end products. |

Choose the best method based on your design and target market.

Packaging Strategies for Efficient Slipper Production

Your packaging protects your product during shipping and is often the first thing people see. Use good, sturdy, environmentally friendly materials whenever possible. Make sure your packaging looks like your brand. To save money, make sure you’re not shipping a bunch of air. Get the right size box so you can fit more units in a shipment.

Quality Control and Supply Chain Risk Management

Even if you have the best materials and processes, you need to have strict quality control (QC) and risk management in place to make sure you get consistent results and deliver on time.

Key Quality Control Checkpoints

| Stage | Inspection Focus |

|---|---|

| Material Inspection | Verify consistency in color, thickness, and flexibility. |

| Mid-Production Testing | Identify issues early, such as weak glue bonds or improperly molded components. |

| Final Product Audits | Confirm durability, appearance, and packaging meet standards. |

Implement QC checks at these critical stages to ensure the quality of your products.

Managing Supply Chain Risks

Delays, running out of materials, and quality problems will shut you down. To mitigate these risks:

- Build relationships with multiple suppliers so you’re not dependent on just one.

- Keep a buffer inventory of your critical materials.

- Use digital tools to monitor and streamline your supply chain in real-time.

Conclusion

Mastering slipper production requires attention to detail at every step, from material selection to quality control. By following these guidelines, you can optimize your procurement and supply chain processes, reduce costs, and deliver high-quality products that customers will love.

Ready to refine your production strategy? Start implementing these best practices today and see the difference they make in your bottom line. If you want to learn more, visit our website and get personal services – WWW.EVASLIPPERS.COM